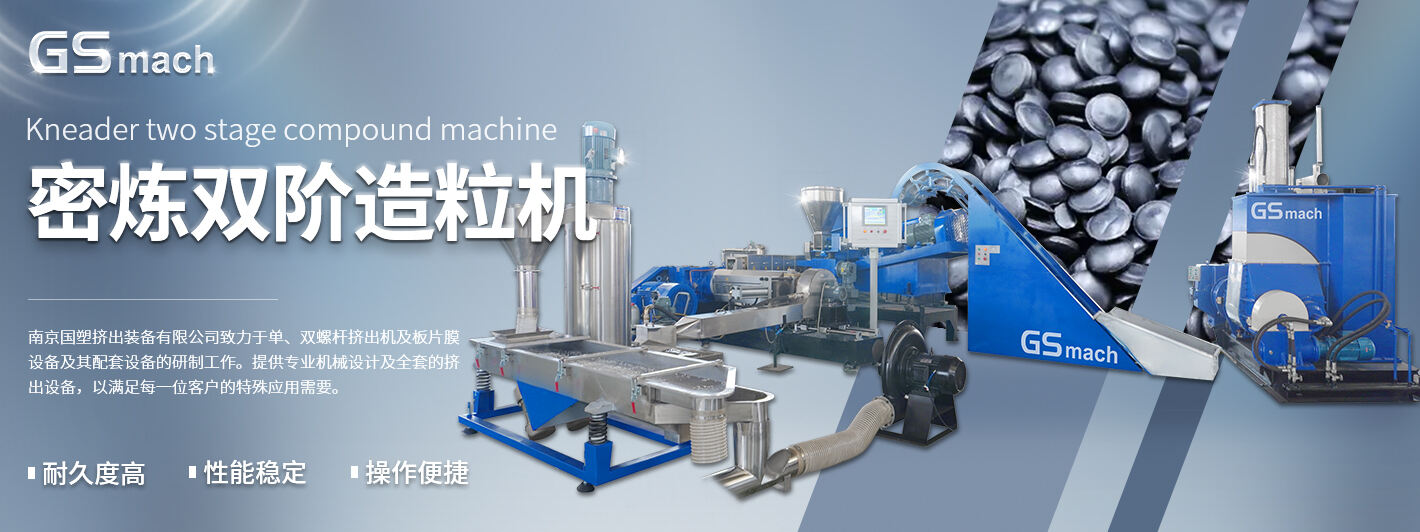

Nanjing GSmach Equipment Co., Ltd,Kami khusus memproduksi sekrup tunggal padat, sekrup ganda padat, granulator dua tahap padat, dengan kualitas terbaik, layanan terbaik, dan tim yang paling profesional untuk membawa produk terbaik kepada pelanggan kami

Pentingnya menggunakan ekstruder kompak untuk meningkatkan produktivitas terletak pada poin-poin berikut:

Produksi Volume Tinggi: Dibandingkan dengan metode produksi lainnya, ekstruder komposit dapat menghasilkan senyawa plastik berkualitas tinggi dengan cepat dan dalam jumlah besar, meningkatkan efisiensi produksi.

Ekonomis dan hemat biaya: Karena ekstruder komposit dapat mencampur beberapa bahan mentah secara bersamaan, hal ini mengurangi biaya produksi dengan mengurangi tenaga kerja manual dan input peralatan selama proses produksi.

Kontrol presisi: Ekstruder komposit memiliki sistem kontrol suhu, tekanan, dan gesekan yang presisi, yang memastikan homogenitas dan stabilitas kualitas komposit plastik untuk memenuhi kebutuhan pelanggan.

Meningkatkan produktivitas ekstruder komposit sangat penting bagi industri modern. Mesin seperti ini sangat vital di bidang seperti plastik, karet, dan kimia, karena dapat mencampur berbagai macam bahan mentah dan memprosesnya menjadi campuran homogen pada suhu tinggi dan tekanan tinggi. Peningkatan produktivitas mesin-mesin ini dapat menghasilkan kecepatan produksi yang lebih cepat, biaya produksi yang lebih rendah, serta peningkatan kualitas dan konsistensi produk.

Selain itu, seiring dengan permintaan pasar yang semakin menekankan pada perkembangan berkelanjutan, peningkatan efisiensi produksi dari mesin pencampur ekstrusi juga dapat mengurangi limbah material dan sumber daya, serta mendorong perlindungan lingkungan dan perkembangan berkelanjutan.

Bagaimana cara meningkatkan produktivitas mesin?

Peningkatan produktivitas mesin adalah proses komprehensif yang perlu dioptimalkan dari berbagai sudut pandang. Berikut beberapa aspek utama:

Pemilihan bahan baku yang sesuai

Pilih bahan baku dengan kualitas stabil dan biaya yang wajar, dan hindari penggunaan bahan baku berkualitas buruk atau tidak terpercaya untuk memastikan stabilitas dan konsistensi kualitas produk.

Atur suhu dan tekanan ekstrusi

Selama proses produksi, suhu ekstrusi dan tekanan perlu disesuaikan sesuai dengan karakteristik bahan baku dan persyaratan produksi untuk memastikan keseimbangan antara kualitas produk dan produktivitas. Jika suhu dan tekanan terlalu tinggi, dapat menyebabkan ausnya peralatan dan pemborosan energi; jika terlalu rendah, kualitas produk dan kapasitas produksi mungkin akan terganggu.

Mengoptimalkan desain cetakan

Cetakan adalah salah satu faktor utama yang menentukan kualitas produk, dan mengoptimalkan desain cetakan dapat secara signifikan meningkatkan produktivitas dan kualitas produk. Misalnya, mempertimbangkan struktur, ukuran, dan pengolahan permukaan produk dalam desain cetakan dapat mengurangi tingkat limbah dan meningkatkan kecepatan produksi.

Memilih transmisi yang efisien

Rantai penggerak adalah salah satu komponen terpenting dalam produksi mesin. Memilih rantai penggerak yang efisien dapat meningkatkan produktivitas mesin. Sebagai contoh, penggunaan inverter frekuensi memungkinkan regulasi kecepatan motor, sehingga membuat proses produksi lebih fleksibel dan efisien.

Perawatan dan perbaikan rutin

Mesin memerlukan perawatan dan perbaikan rutin untuk memastikan bahwa mereka berfungsi dengan baik. Hal ini mengurangi tingkat kegagalan dan waktu pemadaman serta meningkatkan produktivitas. Contohnya termasuk membersihkan peralatan, mengganti habisan, dan memeriksa bagian mesin.

Kesimpulannya, peningkatan produktivitas mesin memerlukan pertimbangan menyeluruh tentang bahan baku, proses produksi, pemilihan peralatan, dan faktor lainnya, serta membutuhkan optimasi dan perbaikan berkelanjutan.

Ringkasan

Dengan perkembangan ilmu pengetahuan dan teknologi serta meningkatnya kesadaran masyarakat terhadap perlindungan lingkungan dan pembangunan berkelanjutan, masa depan mesin pencampur dan ekstrusi pasti akan bergerak menuju arah yang lebih efisien, cerdas, dan hijau.

Di satu sisi, penerapan teknologi digital dan sistem otomasi dapat lebih lanjut meningkatkan efisiensi produksi dan kualitas; di sisi lain, peningkatan kesadaran lingkungan juga akan mendorong pencampur ekstruder dalam pemilihan bahan baku dan proses untuk lebih memperhatikan perlindungan lingkungan, dan secara bertahap berubah ke arah pembangunan berkelanjutan.

Singkatnya, masa depan pencampur ekstruder akan menjadi industri baru yang menggabungkan efisiensi tinggi, kecerdasan, dan perlindungan lingkungan, memberikan kontribusi yang lebih besar bagi perkembangan ekonomi global.

Secara keseluruhan, untuk meningkatkan efisiensi produksi ekstruder pemurnian sangat penting bagi perusahaan. Hanya dengan terus mendorong inovasi teknologi dan meningkatkan efisiensi kita bisa tetap tak terkalahkan dalam persaingan pasar yang semakin sengit.