Parallel Twin Screw: The Invention towards Quality and Safety.

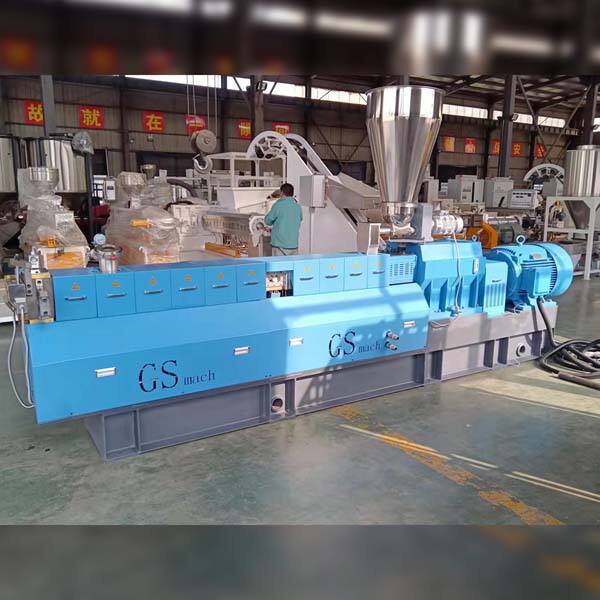

Are you worried about how to improve the quality and ensure that your products are safe for use? Worry no more, along with GSmach's product eva film making machine. A parallel twin-screw is an invention revolutionizing manufacturing. It has dozens of advantages we will face here. Let me start with a rundown on how it is used, it is application, and what kind of results in service you may expect.

There are a few major benefits of Parallel Twin Screw equipment and known to have the following few major benefits over their counterparts:

Increased efficiency: The throughput of Parallel Twin Screw can be very high in comparison with other equipment, and in turn, this will lead to increased productivity and cost degradation, just like the counter rotating extruder made by GSmach. This can happen by the reason that the product is built by screws in a smooth and continuous manner, resulting in homogeneity and constancy of the product.

2. Improved Quality Mixing: The Parallel Twin Screw offers better quality mixing compared to other machines. This is because of screws that are corotating, due to which one can regulate residence time of the product apart from the mixing quality.

3. High Versatility: The Parallel Twin Screw is highly versatile and has the capacity to handle many products with ease, ranging from solids, liquids, and gases of varying viscosities and temperatures. Just that fact makes it a perfect solution for many applications in need of the same machine. 4. Low Maintenance: Parallel Twin Screw enjoys an aspect of low maintenance due to it is robust nature, which ensures that the machine works perfectly well. It is also coupled with wear parts that are fewer than any other equipment, hence depreciating it is rate of replacement.

The technology that led to the emergence of the Parallel Twin Screw, being in consideration of innovations that had safety as a priority, has a design making it better and safe as compared to other choices in the market, the same as GSmach's plastic strand pelletizer. The equipment is designed to assure perfect alignment in clearances that minimize the level of risk involvement from accidents and explosions, given the fact that they use intermeshing rotors.

The equipment is also easy to operate, with simple controls and clear displays that make it simple to use. This reduces the chances of human error, making it an ideal choice for industries that prioritize safety.

The Parallel Twin Screw is user-friendly, with straightforward controls that any person can pretty much grasp. Nevertheless, it can hardly be emphasized enough that the instructions and safety precautions included with the unit should be reviewed before the machine is handled. The person shall also see to it that the apparatus has been mounted properly and has passed the safety tests before use.

Then there is preparation of the product for processing. This may involve mixing various ingredients, heating them, or cooling them according to an application. The screws are rotated, and the product moves through the machine from feeding through to the inlet of the Parallel Twin Screw.

The product will be subjected to intense mixing and shearing action through this equipment to be sure that a consistency of homogenous products will be established as the product pass through. The product can then be collected from the outlet all ready for further processing or packaging.

Top of the list at Parallel Twin Screw is quality service to all our customers. We believe that apart from the quality of goods, our customers also need quality after-sales services, so that our equipment can give the best possible performance. Part of this support includes giving service support to our clients by running training for them on usage and maintenance of the equipment for efficiency.

We make sure that all our equipment is of the highest quality and that only top-quality materials and components are utilized in order to ensure endurance and long operation, same with the small pelletizer developed by GSmach. We also have provisions for customization, which literally means that we design the equipment fully considering the client's need.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with parallel twin screw.

GSmach is a frontrunner in China for extruded Polystyrene Equipment and is parallel twin screw with world-class companies like BASF, Owens Corning ISOFOAM Ravago and others. Our record of success demonstrates our commitment to excellence in delivering world-class industry leading companies.

Your machines are designed to stay in line with overseas safety and standard of quality. We offer affordable solutions. Save as much as parallel twin screw with other European manufacturers. Our skilled team and multilingual service ensure both happy appliances and unbeatable customer service.

Our expert technical engineers and technicians are available to assist you to your journey. User're right here to help you overcome obstacles and improve might parallel twin screw of your production. People offer 24/7 remote technical maintain with cutting-edge, intelligent technology.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy