News

-

Join GSmach at IPF Bangladesh 2025!

2025/02/05Join GSmach at IPF Bangladesh 2025! Date: February 12-15, 2025 Booth: 396 Discover cutting edge plastic extrusion solutions from GSmach! From Twin screw extruders to advanced plastic sheet extruder machines,Biodegradation granulation turnkey project,...

-

Join GSmach at TCT ASIA 2025!

2025/03/18We're thrilled to announce that GSmach will be showcasing our latest innovations at TCT ASIA 2025, happening from March 17-19, 2025, in Shanghai, China. Visit us at Booth 8J30 and explore our advanced solutions for the 3D printing and extrusion indus...

-

Join GSmach at RUPLASTICA 2025 in Moscow – Booth 23F10!

2025/01/21We are thrilled to announce our participation in RUPLASTICA 2025, one of the leading international exhibitions for plastics and rubber industries. From January 21-24, 2025, we invite you to visit us at Booth 23F10 at the Expocentre in Moscow, Russia....

-

Wishing You a Joyous Christmas and a Prosperous New Year!

2024/12/24Wishing You a Joyous Christmas and a Prosperous New Year! Dear Valued Partners and Friends, As the festive season approaches, we at GSmach would like to extend our heartfelt gratitude for your trust and support throughout this year. May your Christm...

-

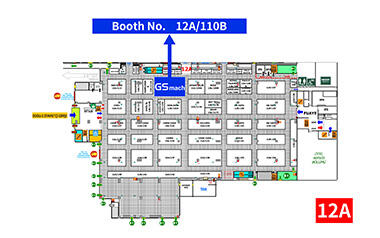

Explore the future of plastic extrusion with GSmach at Plast Eurasia Istanbul 2024!

2024/09/14"Explore the future of plastic extrusion with GSmach at Plast Eurasia Istanbul 2024! Visit us at Booth 12A/110B to see our advanced twin screw extruders and kneader/banbury machine in action. GSmach is dedicated to delivering precision, efficiency, ...

-

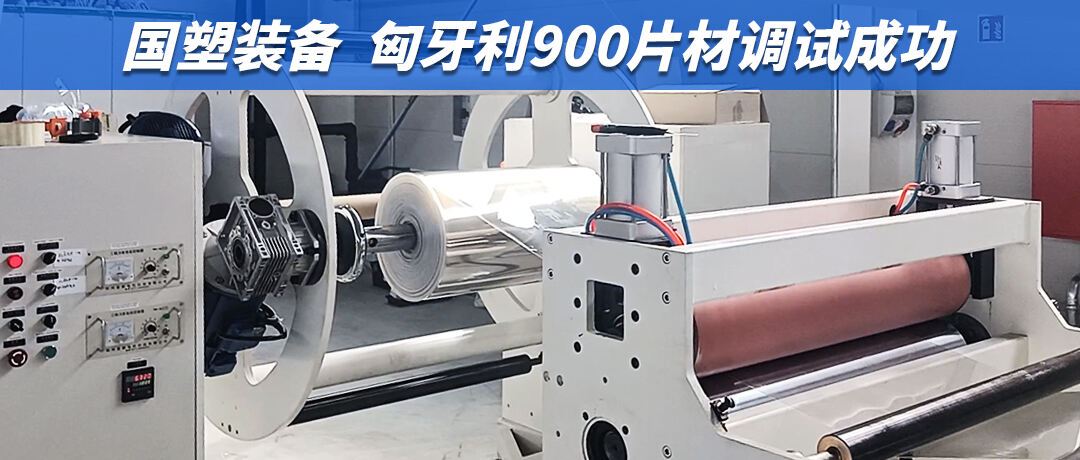

The 900mm PET sheet machine successfully commissioned in Hungary is an efficient machine with advanced technology, which can provide customers with high quality PET sheets.

2024/09/061. Device featuresWidth 900mm: suitable for a wide range of downstream processing needs, especially in the packaging and industrial sectors.Efficient production: the equipment is equipped with advanced extrusion system, to ensure high yield, and can...

-

Metering feeding system +2 110L mixer +GSD180 single screw extruder hot cutting granulator

2024/08/301. Metering feeding systemThe metered feeding system plays a vital role in the entire plastic processing process. Its main function is to ensure that each raw material (such as resins, additives, masterbatches, etc.) is delivered to the mixing equip...

-

3D printing filament extruder machine new upgrade

2024/08/23Our upgraded filament extruder machines offer significant advantages, combining a number of advanced technologies: 1. Servo control: To ensure the stability of extrusion line diameter, greatly improve product consistency and quality.2. The entire PL...

-

The GS35 Laboratory twin-screw extruder is designed for laboratory-scale applications. It is commonly used in research and development, material testing, and small-scale production.

2024/08/16Compact design: The GS35 design saves space and is ideal for laboratory environments where space is limited. High precision: It can precisely control temperature, screw speed and torque, suitable for testing different formulations and processing con...

-

Double GSmach 75/180 order under water pelleting machine is a specially designed for high quality plastic granulation equipment systems.

2024/08/09Double stage extruderSettings:The first stage deals with the initial melting and mixing of polymer materials.The second stage: further mixing, homogenizing and providing pressure for extrusion.Advantages:Improved mixing: The two-stage configuration ...