News

-

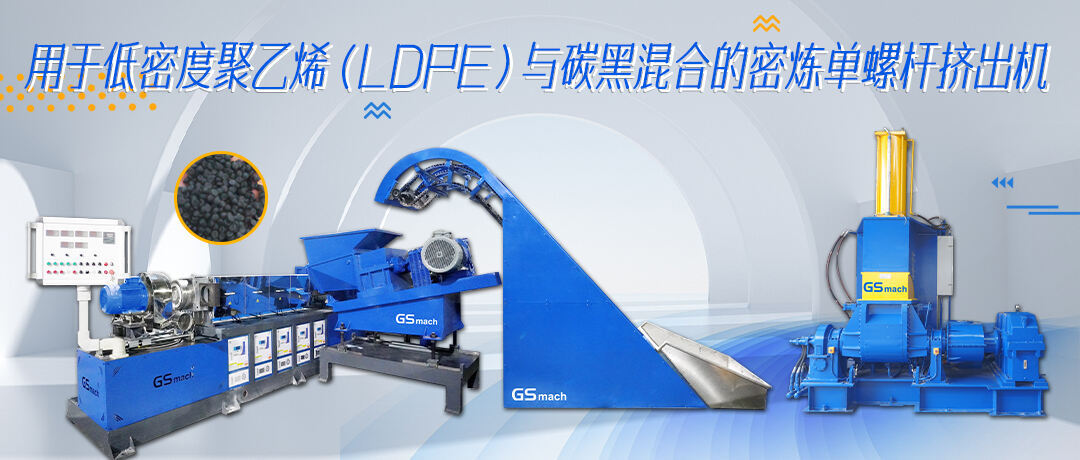

Single screw extruders for mixing low density polyethylene (LDPE) with carbon black

2024/08/02Components and functions: Feeding system:Cone double feeder: The mixed low density polyethylene particles and carbon black are fed into the extruder.Weight or volume feeders: Used to precisely control the feeding rate of each component. Extruder bar...

-

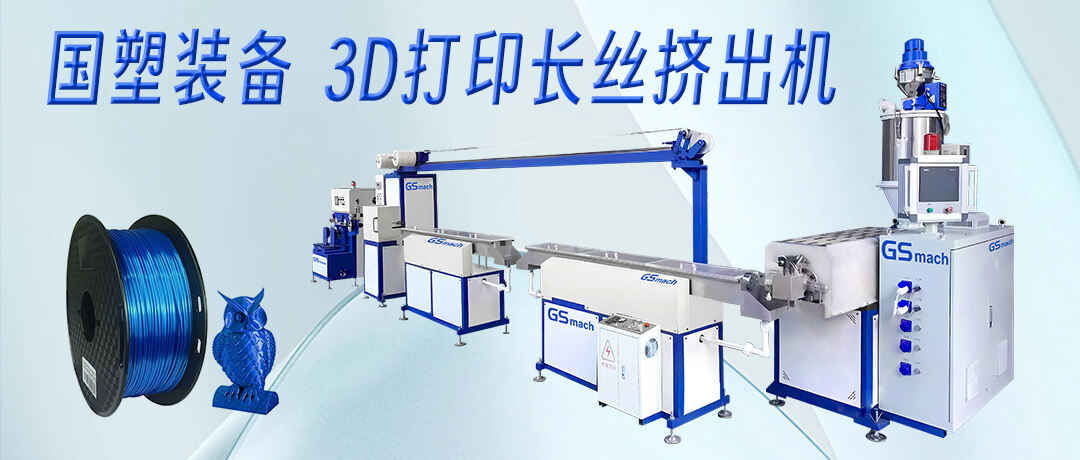

A 3D printing filament extruder is a device that converts plastic raw materials (usually in granular form) into filaments suitable for use by 3D printers. The process involves heating the plastic until it melts, then extruding it through a nozzle to form

2024/07/26The importance of 3D printing filament extruderFilament extruders are critical in the 3D printing industry for several reasons:Cost effective: Producing filaments in-house can greatly reduce costs compared to purchasing prefabricated filaments.Custo...

-

Factory machines

2024/07/22- Torque:*GSD high-torque twin-screw extruders: With higher torque, usually achieved through a more robust gearbox and motor. This allows higher viscosity materials to be processed and higher yields achieved.*GS twin-screw extruder: low torque, suit...

-

General debugging steps of 3D printing filament extruder machine production line

2024/07/12Step 1: Check before startingVerify temperature control responsiveness of all heating zones (feed zone, compression zone, metering zone).Ensure all instruments are working properly, including temperature controller, pressure gauge and motor ammeter....

-

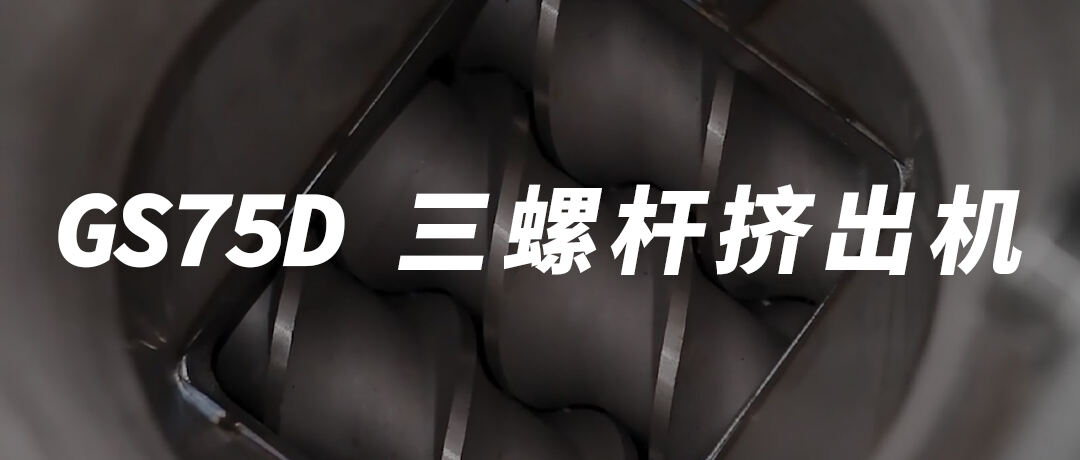

GS75D triple screw extruder

2024/07/05Type: three screw extruderModel: GS75DSuitable for: laboratory, research and industrial applicationsMain features: Includes three screws for enhanced processing power Functions and componentsThree screw mechanism:Superior mixing, kneading and mixing...

-

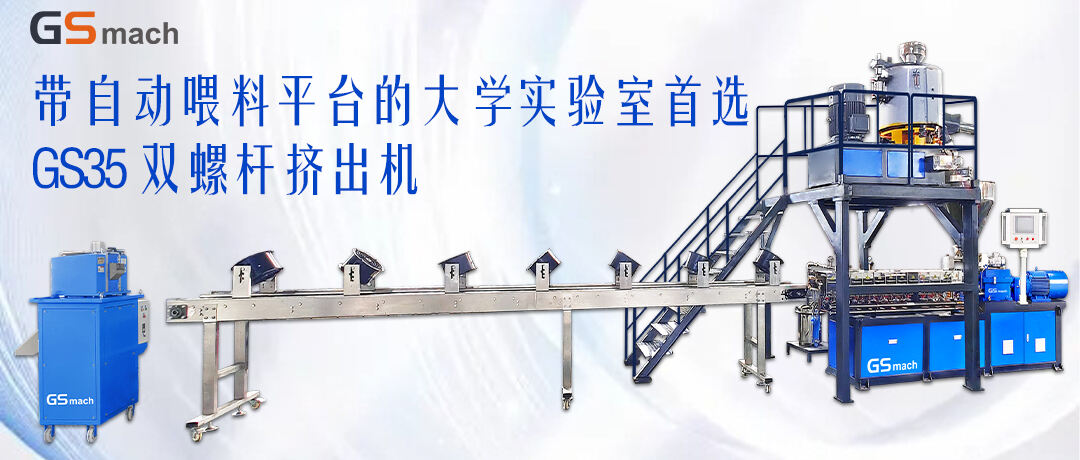

The GS35 twin-screw extruder is the first choice for university laboratories with automatic feeding platforms

2024/06/28Type: Twin screw extruderModel: GS35Preferred for: laboratory or university researchMain features: Designed to avoid moisture during processing Features and componentsTwin-screw mechanism: Efficient mixing and batching.Provides high shear force to e...

-

The twin-screw extruder is an innovation that has revolutionized the plastics industry. Compared with single-screw extruders, twin-screw extruders have many advantages. This extruder is superior to single-screw extruders in terms of performance, efficienc

2024/06/21This article will delve into the advantages of twin-screw extruders and how these advantages enable them to improve efficiency and productivity in the plastics manufacturing process. Here are some of the advantages of twin-screw extruders. Twin scre...

-

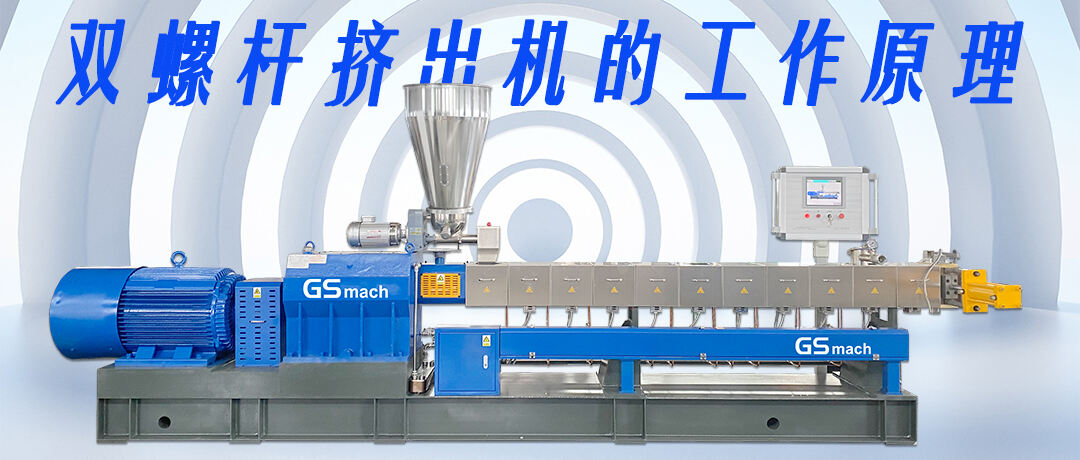

Working principle of twin-screw extruder

2024/06/14The structure of the twin screw extruder and single screw extruder is very similar, but its working principle is different. In a single screw extruder, the material transport depends on the friction and viscous resistance of the material, so the res...

-

PBT masterbatches are used in the production of POY&FDY:

2024/06/07Key points:1. The low viscosity process:PBT has a lower viscosity than PP, so a specially designed screw is required.- Use a small extruder to ensure minimum clearance between screw and barrel and improve mixing efficiency. 2. Raw material preparati...

-

We are very pleased to announce that the stone paper equipment is now complete with a new upgrade! This upgrade not only improves production speed and capacity, but also comprehensively optimizes many aspects, making our equipment a leader in the industry

2024/05/311. Faster production speed We use the latest technology and materials to greatly increase the speed of the production line. By optimizing the mechanical structure and control system, the new equipment is able to process more raw materials per unit t...