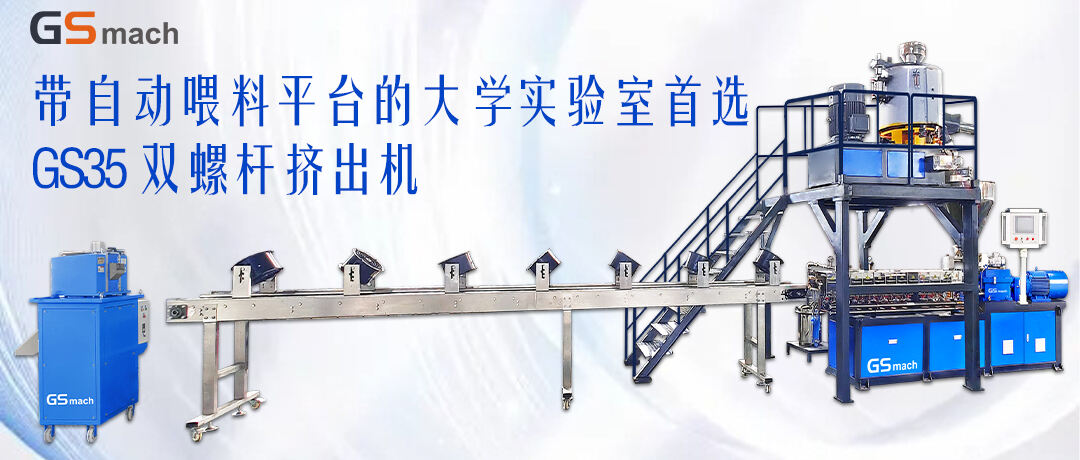

The GS35 twin-screw extruder is the first choice for university laboratories with automatic feeding platforms

Type: Twin screw extruder

Model: GS35

Preferred for: laboratory or university research

Main features: Designed to avoid moisture during processing

Features and components

Twin-screw mechanism: Efficient mixing and batching.

Provides high shear force to ensure thorough mixing.

Moisture proof:

Includes components that minimize or eliminate moisture in material intake and processing areas.

Ensure the quality and consistency of the final product.

Automatic feeding platform:

The material is stably and controllably fed into the extruder.

Reduce manual intervention and improve process reliability.

Apply

R&d: Ideal for testing different materials and formulations.

Materials science: Used to study the properties of various polymers and composites.

Industrial process simulation: Large-scale industrial processes can be simulated in a small range for easy management.

advantage

Accurate: highly on extrusion process for control, to ensure the repeatability of the result.

High efficiency: reduce material waste and optimize resource utilization.

Flexibility: Suitable for a variety of materials and applications.

If you need specific details about the extruder, such as technical specifications, operating guidelines or maintenance procedures, please provide more information or ask specific questions!