Polycarbonate Sheet Extrusion: The newest and Safe answer to Your requirements for Clear Plastic

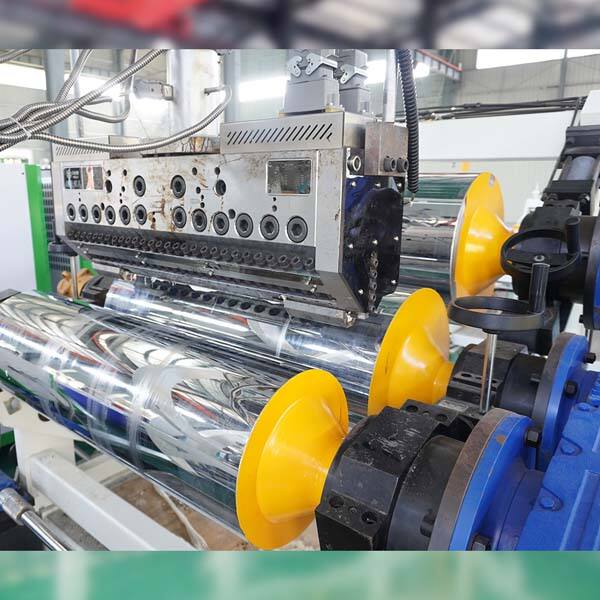

Are you currently hunting for a versatile, sturdy, and material safe your construction, signage or requirements that are commercial? Look no further than polycarbonate sheet extrusion, we covers advantages that could be amazing features, and safe characteristics of Polycarbonate Sheet Extrusion, as well as the GSmach's two screw extruder. We will provide informative data on how to use Polycarbonate Sheet Extrusion the ongoing services created for them, their quality, and their applications.

Polycarbonate sheet extrusion has advantages that could be numerous other materials such as glass, acrylic, and PET, also the masterbatch manufacturing machine developed by GSmach. Firstly, it is more shatter-resistant and durable than acrylic or glass. A opposition high effect and can withstand extreme weather, rendering it perfect for outside signage and constructions in addition features. In addition, polycarbonate sheets are incredibly lightweight, making them an easy task to manage and transport, and cost-effective. Also easier to fabricate than acrylic or cup, allowing for substantially more designs which can be complex customization.

The innovation of polycarbonate sheet extrusion has revolutionized the plastic industry. The growth of multiwall polycarbonate sheets has increased the insulation value and allowed for greater design flexibility. These sheets offer UV security, making them ideal to be used in greenhouses, skylights and roofing.

Another function the energy to produce Polycarbonate Sheet Extrusion in various colors in accordance with different finishes such as frost or mirrored, as well as the GSmach's cast film line. This enables more design options and appeal aesthetic.

Polycarbonate sheet extrusion can also be incredibly safe, the same as plastic flakes recycling machine innovated by GSmach. It is retardant very flame which makes it a safer option than other plastic materials. It is additionally very easy to wash and disinfect, that makes it perfect to be utilized in hospitals and meals processing. Furthermore, polycarbonate sheets are non-toxic and do not release harmful chemicals into the environment, making them eco-friendly.

Polycarbonate sheet extrusion is very versatile and therefore can be properly employed for a number of applications such as roofing, skylights, partitions, greenhouses, and machine guards, same with GSmach's pet granulator. It might be drilled and cut effortlessly, making it customizable and adaptable to almost any project. Polycarbonate Sheet Extrusion can be thermoformed or bent directly into a number of shapes, making it possible for complex designs and expression artistic.

We were established in 2003 and concentrate on polymer extrusion machines and Polycarbonate sheet extrusion. We've shipped more than 2,500 double screw units. Rely in our vast expertise and nonstop help for your extrusion needs.

GSmach leads the market for Polycarbonate sheet extrusion in China, collaborating with renowned international companies such that BASF, Owens Corning, ISOFOAM, Ravago, and various others. Our track record proves our dedication to serving industry management around the world.

Our equipment is in line with international standards of safety and quality offering efficient systems. Salvage significant amount, up to 40%, in contrast to different Polycarbonate sheet extrusion. Our expert team and multilingual service ensure both pleased products and unmatched customer service.

Enhance your production with our Polycarbonate sheet extrusion and professionals. We are ready to help you overcome your challenges and augment your production's performance. With cutting-edge technology for intelligent get a grip on, at this time seamless, remote and accurate tech support team to guarantee that your businesses run effectively.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy