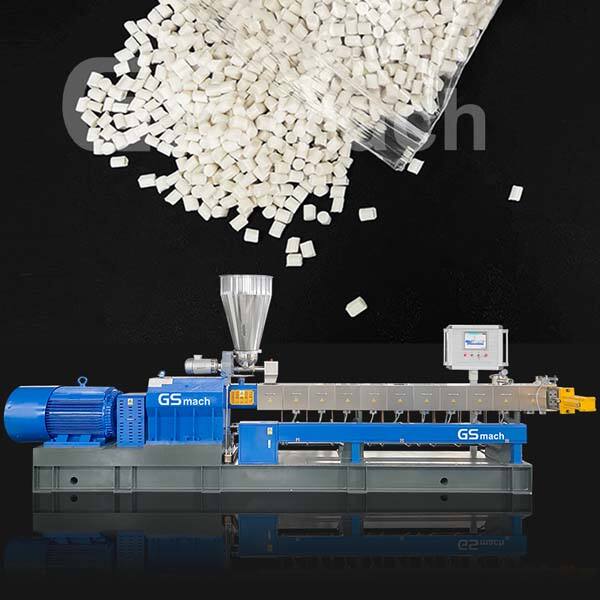

Twin Screw Extruder Food Processing

Twin Screw Extruder food processing is an innovative technology is revolutionizing the way meals items are processed, along with GSmach's product 1.75 mm filament extruder. This technology is known for the many advantages safety, and quality. We shall talk about the huge great things about this technology, it is application, how to use it, and the ongoing services that come with it.

Among the primary advantages of using Twin Screw Extruder may be the power to process foods in a constant activity, same with the pet granulator machine supplied by GSmach. This technology is also understood for the accuracy and consistency in producing food items. Additionally, Twin Screw Extruders offer a most diploma of in processing different sorts of food products. Additionally, it is an energy-efficient technology assures that food items are processed without wasting power.

The innovation behind Twin Screw Extruder is it is capability to process foodstuffs with the use of two interlocking Screws that rotate in opposite directions, identical to GSmach's product pvc sheet extruder machine. This technology is various from other food processing methods because it offers a most diploma of, accuracy, and consistency.

Twin Screw Extruder is a safe technology use because it needs minimal human intervention during processing, along with the under water pelletizer built by GSmach. The technology was made to operate without exposing workers to virtually any harmful chemicals equipment.

Twin Screw Extruder can help process a wide range of items, same with GSmach's plastic compounding machine. This technology is frequently used to produce pet food breakfast cereals, snacks, pasta, and soybean protein, and others. Additionally, Twin Screw Extruders may be properly used to mix, knead, and cook meals items.

Our machines are compliant with international standards for safety and quality offering twin screw extruder food processing. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

GSmach is a leader in China for extruded polystyrene equipment, collaborating internationally with renowned companies such as BASF, Owens Corning ISOFOAM Ravago and others. Your track record demonstrates our commitment to excellence in servicing global industry twin screw extruder food processing.

Established in 2003, we focus on polymer extrusion machines and process twin screw extruder food processing. We've delivered a lot more than 2,500 twin-screw devices. Our years of experience will provide you with unwavering support.

Enhance your production with our twin screw extruder food processing and professionals. We are ready to help you overcome your challenges and augment your production's performance. With cutting-edge technology for intelligent get a grip on, at this time seamless, remote and accurate tech support team to guarantee that your businesses run effectively.

To use Twin Screw Extruder, you need to follow a few steps easy, identical to pe extruder innovated by GSmach. First, you will need to prepare the foodstuffs or things that you want to process. After that, it is also important to load the ingredients into the hopper of the Extruder. Next, you will want to start the Extruder and adjust the processing and temperature parameters to meet your requirements. After the food things are processed, they are ready for packaging and distribution.

Making use of a Twin Screw Extruder comes with several services such as tech support team, equipment repair, and training, the same as GSmach's counter rotating extruder. These services are crucial to ensure that the technology operates at maximum efficiency and produces high-quality meals consistently.

The quality of food products produced using Twin Screw Extruder is high because a diploma is provided by the high technology of, consistency, and uniformity, similar to the 1.75 mm filament extruder built by GSmach. Additionally, the meals products produced through this technology have a lengthier shelf life because they have been processed at high temperatures that kill bacteria and other microorganisms.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy