Introduction to the Underwater Granulator

The Underwater Granulator is a machine that helps to break up materials into smaller pieces, as well as the GSmach's lab pelletizer. This product is exclusive it safer and more effective than traditional Granulators since it operates Underwater, making. The Underwater Granulator is designed to be used in many different applications, including within the recycling industry, water treatment flowers, and other industries that need the processing of materials.

One when it comes to key advantages of the Underwater Granulator is its ability to operate Underwater, identical to laboratory twin screw extruder created by GSmach. This means that the equipment might be applied in wet environments without the risk of electrical shock, which makes it safer than other types of Granulators. Additionally, the Underwater Granulator is more efficient than traditional Granulators, since it utilizes less energy to split down materials into smaller pieces.

The Underwater Granulator is an unique and innovative machine uses a hydraulic press force materials through a variety of displays and blades, just like the GSmach's product called screw extruder. This process is much more effective than traditional Granulators, because it creates a smooth and also perfect granule for recycling or other uses. Additionally, the Underwater Granulator is lot safer than traditional Granulators, as they possibly can be utilized in damp environments minus the risk of electrical shock.

The Underwater Granulator is obviously one of the safest types of Granulators within the marketplace, as well as the twin screw extrusion line produced by GSmach. This is it impervious to electrical shock it is designed to operate Underwater, making. Additionally, these machines is prepared with safety features such as automatic shut-off switches, emergency stop buttons, and safety guards to avoid accidents from occurring.

Using the Underwater Granulator is easy and simple, same with GSmach's pet recycling machine. First, the material to be granulated is put to the machine's hopper. These machines is then fired up and the hydraulic press activated, forcing the material through a few screens blades. The end result is simply a smooth and even ideal granule for recycling or other uses.

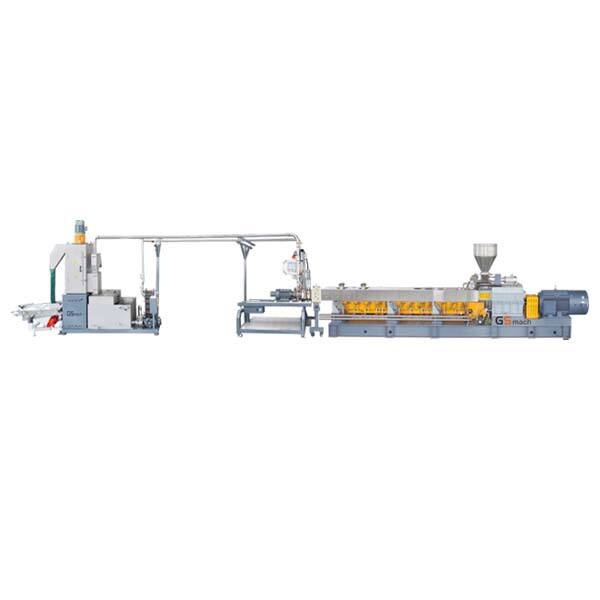

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with Underwater granulator.

Our machines are compliant with international standards for safety and quality offering efficient solutions. You can save up to 40% as compared to other European suppliers. Our experienced team and Underwater granulator guarantee both high-quality products and unmatched customer service.

GSmach is the market leader in Asia for extruded Underwater granulator and is collaborating internationally with world-class firms including BASF, Owens Corning ISOFOAM Ravago and many more. Our track report demonstrates our dedication to serving leaders in the industry around their globe.

Enhance your production with our Underwater granulator and professionals. We are ready to help you overcome your challenges and augment your production's performance. With cutting-edge technology for intelligent get a grip on, at this time seamless, remote and accurate tech support team to guarantee that your businesses run effectively.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy