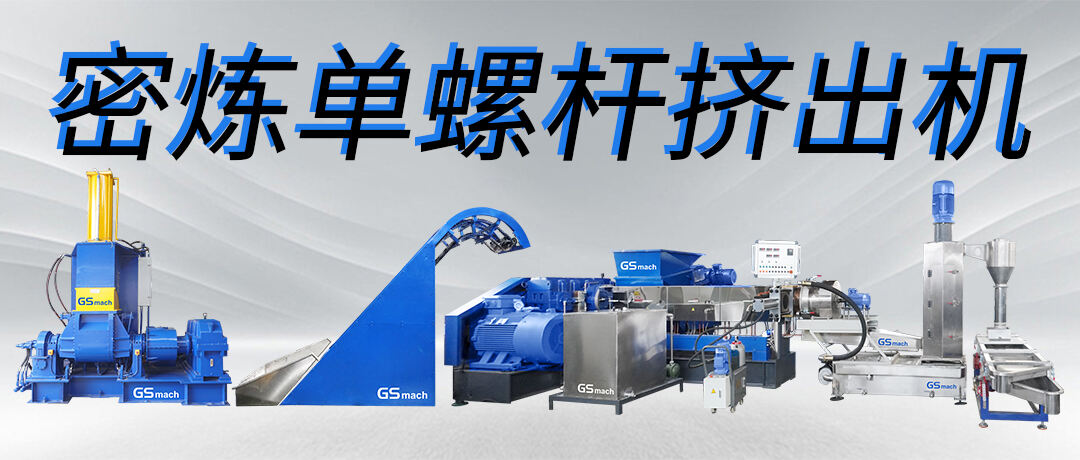

Dense single screw extruder is a kind of equipment commonly used for making plastic pellets, which is also suitable for making carbon black masterbatch. When making carbon black masterbatch, the usual process flow is as follows:

1. Raw material preparation: Prepare and weigh the raw materials such as polymer base material and carbon black filler according to certain formula ratio.

2. Mixing and processing: The pre-formulated raw materials are put into the refiner for mixing and processing. Through the friction heat of the rotating screw and barrel inside the refiner, the polymer and carbon black filler are fully mixed and heated to melt, so as to reach a homogeneous mixing state.

3. Extrusion molding: After the mixing process, the material is fed into the single-screw extruder, where it is further melted and extruded through the rotation of the screw and external heating. In the extruder, the material passes through the extrusion outlet die to form a continuous masterbatch.

4. Cooling and cutting: After the extruded carbon black masterbatch is cooled, it is cut into the required length by the cutting device, and cooled during the cutting process to prevent the masterbatch from sticking.

5. Packaging and Storage: The cut carbon black masterbatch is bagged or stored in containers for subsequent processing or sales use.

Advantages:

1. efficient production: dense single-screw extruder with high production efficiency, can quickly mix the raw materials, melt and extrusion molding, improve production efficiency, save time and cost.

2. homogeneous mixing: through the mixing and processing of single-screw extruder, can be carbon black and other fillers and polymer substrate fully mixed, to ensure the quality of carbon black masterbatch stability and consistency.

3. Precise control: the extruder is equipped with advanced control system, which can accurately control the parameters of extrusion temperature, pressure and extrusion speed to ensure the stability and controllability of the production process and improve the stability of production and product quality.

4. Energy saving and environmental protection: compared with the traditional production methods, the dense single screw extruder can save energy and reduce waste in the production process, which has better energy saving and environmental protection effects and meets the requirements of sustainable development of modern manufacturing industry.

5. Strong production adaptability: the dense single-screw extruder is suitable for different types of polymers and different ratios of carbon black filler, with strong production adaptability and flexibility, to meet the needs of different customers, improve the flexibility and diversity of production.

When making carbon black masterbatch, the dense single-screw extruder can effectively mix and process the raw materials to ensure the quality and stability of the masterbatch, which is suitable for industrial production in the fields of plastic products manufacturing, rubber products manufacturing and so on.