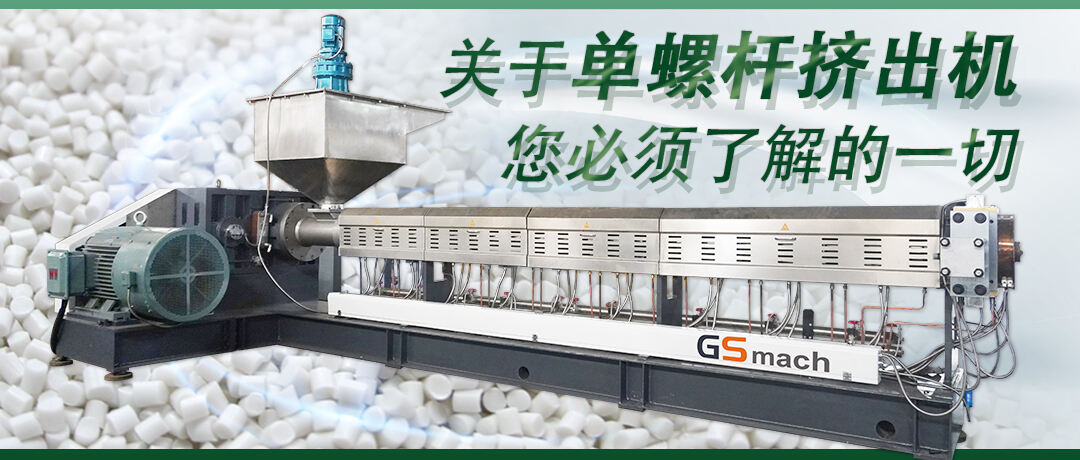

Everything You Must Know About Single Screw Extruders

Single screw extruders typically melt continuously, then compress and extrude inside a heated barrel to form a solid material.

Single-screw extruders have actually evolved from basic screw configurations, such as dampening screw blocks, slotted screw barrels, exhaust screws, building block configurations, pin barrels, and many other different types of configurations.

Since single screw extruders generally take up less space, they have become the main equipment used in the fields of composite processing and blown film for plastics.

Extrusion is a process of making a product by forcing a material through an orifice or die to form a certain shape. Alternatively, the extruder will be used to produce semi-finished/finished products.

Structure

Basically, a single screw extruder consists of a screw, a drive mechanism, a barrel, a resin feeding device and various control devices. The resin is moved through the heated barrel by the constantly rotating screw, which heats the resin to the right temperature and then mixes it into a certain homogeneous melt.

Turbulent back pressure will build up, thus pushing the melt out of the extruder in the form of a mold. Sometimes the resin may not melt completely in the basic extrusion screw. To solve this problem, there will be a barrier screw. Often, there are additional threads attached to its transition section to separate the molten plastic from the solid plastic into some different channel.

As that solid particle moves forward, it will melt due to the shear force of the wall. As a result, it will melt and flow into the liquid channel. In this way, the solid channels gradually become narrower and the liquid channels gradually become wider.

Over the years, the design of extrusion screws has improved and various new ideas and innovations have emerged. Today, it is possible to use single screws with secondary threads that can increase speed by melting faster.

Single screw extruders can be equipped with many different types of accessories, such as

1. Automatic gravity feeders

2. Heat and pressure controllers

3. Heat exchangers

4. Melt pumps

5. Microprocessor control systems

6.Static and dynamic mixer

7.Exhaust vacuum devices

In addition, they offer screws in various geometries for different products and materials.

Principles

1. The conveying section starts at the last wire of the material opening.

Here the material does not need to be plasticized but preheated and compacted. Earlier, according to the old extrusion theory, it was thought that all material here was loose. But later it was finally proved that the material is actually a solid plug, which means that the material will be solid like any plug after being extruded and hence its role will be to fulfill the total conveying task.

2. The second part is the compression part

The volume of the screw groove, at this point, will gradually become smaller and the temperature should reach the point where the material is plasticized. The compression generated here will come from the third conveying section.

The compression here is called screw compression ratio 3:1. In addition, there are some variations in other machines. Then the plasticized material will go to the third stage.

3. The third part will be the measuring part

Here the material will be kept at the plasticizing temperature, almost like any metering pump for accurate and quantitative delivery of the melt material to supply the machine head. During this period, all temperatures must not fall below the temperature required for plasticization, generally slightly higher.

These single-screw extruders are primarily used for extruding rigid and soft polyethylene, polyvinyl chloride and other thermoplastics. In combination with the appropriate additives, a wide range of different plastic products can be processed, such as pipes, films, sheets, etc. Pelletizing is also possible.

How does it work?

Single-screw extrusion typically uses a single screw located in a cylindrical barrel that continuously pushes plastic through a constant-profile die. Typically, production rates are measured in mass/hour and are controlled by the machine's screw speed.

Advantages and Disadvantages

The advantages of these single screw extruders are advanced design, good plasticization, high quality, low energy consumption, low noise, high load capacity, stable operation and long life.

Single-screw extruders can be designed with two-stage integral design to strengthen the plasticizing function and ensure high speed, stable extrusion and high performance.

The special barrier complete mixing design ensures the mixing effect of materials and high shear and low melting temperature.

Besides that, single screw plastic extruder is quite inexpensive to design and can provide high performance, low temperature and low pressure metering material extrusion, so single screw extruder is very widely used.

There are many single-screw extruder manufacturers in China who can provide you this kind of extruder.

Disadvantage:

Since the transport of any plastic material in a single screw plastic extruder will be through friction, there are some limitations when considering the feeding performance.

Some materials such as powders or pastes have difficulty in the mixing process. This will make the machine unsuitable for use in certain processes.

Areas of Application

The following are some of the applications where the single screw extruder is used to manufacture the following products:

1. Raw materials for other plastics processing: widely used as a mixer or blender. The output of any extruder mixer will be chopped or pelletized to form feed for any other process such as injection molding or extrusion.

2. Filaments: Used for twine, brushes, ropes, etc.

3. Nets: for packaging, soil stabilization, etc.

4. Plastic coated paper and metal: usually used for packaging.

5. Plastic film: usually used for packaging and sealed into bags.

6. Plastic insulated wire: used in industry and home for electrical appliances, power distribution, communication, etc.

7. Plastic pipes: used for gas, water, drainage, etc.

8. Plastic pipes: used in automobiles, tubes and laboratory hoses, etc.

9. Profiles: used for gaskets, home siding, doors, windows, tracks, etc.

10. Sheets: for signs, lighting, glass, etc.