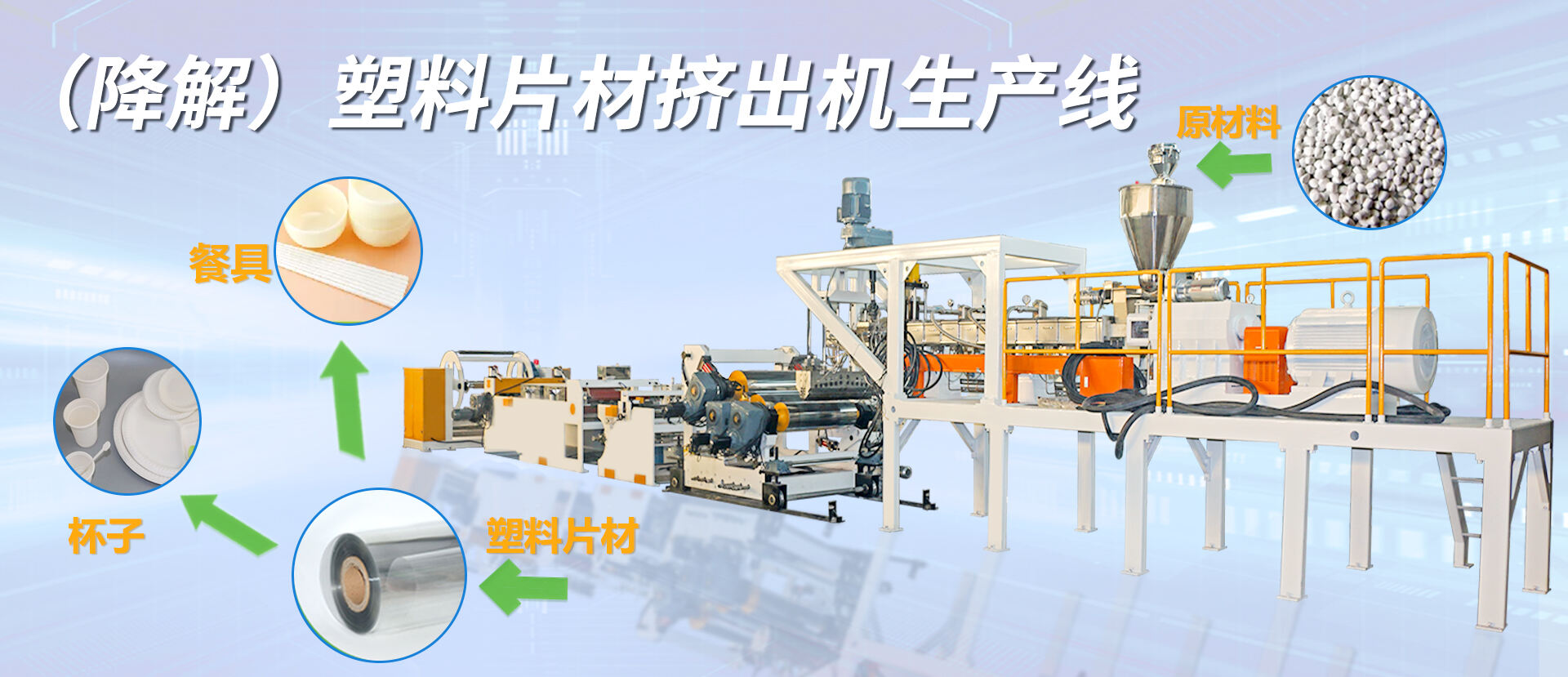

GSmach specializes in the production of sheet extruders, and brings the best products to customers with the highest quality, best service and the most professional team

Nanjing GS-mach Extrusion Equipment Co., Ltd. produced sheet extruder machine, also known as a sheet extrusion line or sheet extrusion machine, is a type of machinery used in the plastic processing industry to manufacture plastic sheets. It is commonly used in the production of various plastic sheet products, including packaging materials, plastic containers, stationery, automotive parts, and construction materials.

1. Extruder: The main component of the machine is the extruder, which consists of a barrel and a screw. The plastic material, usually in the form of pellets or granules, is fed into the barrel. Inside the barrel, the material is melted by heat generated by heaters and forced forward by the rotating screw.

2. Screen Changer: To remove any impurities or contaminants from the melted plastic, a screen changer is used. It helps ensure a clean and uniform melt before the material is extruded.

3. Die: The melted plastic material passes through a die, which is a specially designed tool that shapes the molten plastic into a flat sheet form. The die has an adjustable lip opening, allowing for precise control over the thickness of the sheet.

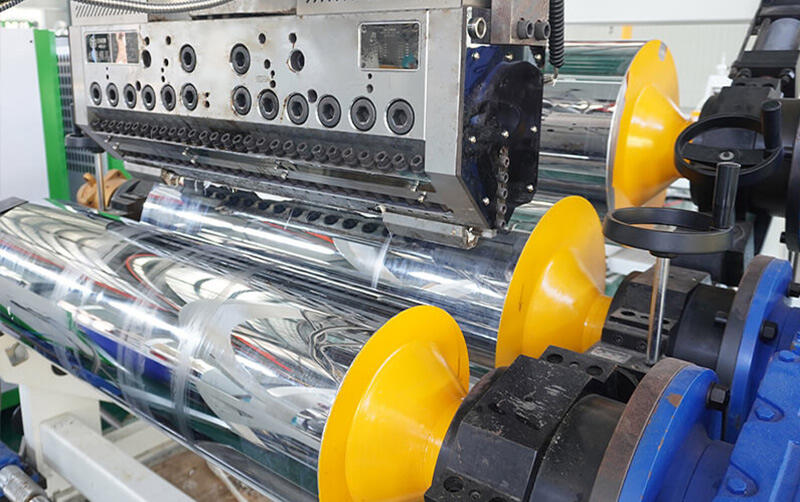

4. Cooling and Calibrating: Immediately after exiting the die, the hot plastic sheet undergoes a cooling process. This can be done using various methods, such as air cooling or water cooling, where the sheet is passed through a cooling system or a series of cooling rollers. This solidifies the molten plastic, shaping it into a solid sheet.

5.Haul-off Unit: Once the sheet is sufficiently cooled and solidified, a haul-off unit pulls the sheet forward at a controlled speed. This helps maintain tension and control the final dimensions of the sheet.