利点

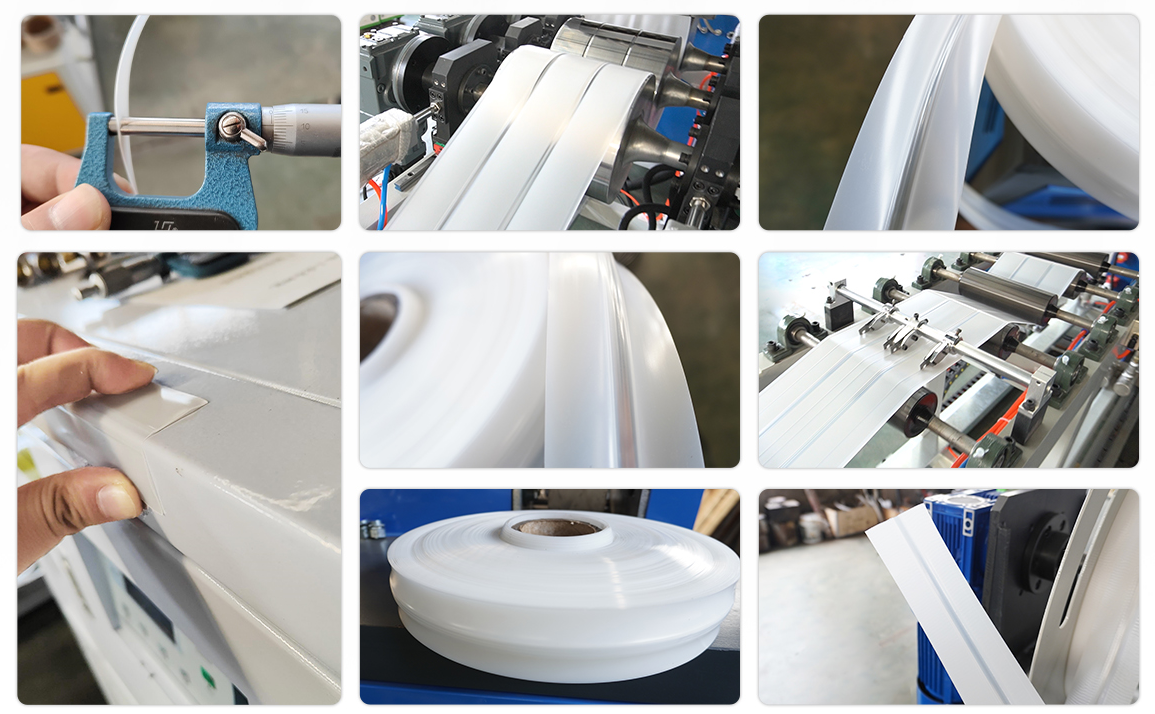

1. PEシートの幅は53〜55mm、厚さは0.5〜0.7mmで、シートサイズは高精度です。シートの中央に折り目があり、包装箱やその他の製品を破損から保護しやすくなります。

2. 10kg/ロールの大ロールに巻き取ることができ、2つのワインダーが装備されており、同時に2つのロールを巻くことができます。

3. 高容量で、少なくとも15メートル/分です。

4. 3つのカッターが装備されており、一度に2枚のシートを作ることができます。

5. 廃材をリサイクルするためのクラッシャーが装備されており、廃材を再利用できます。

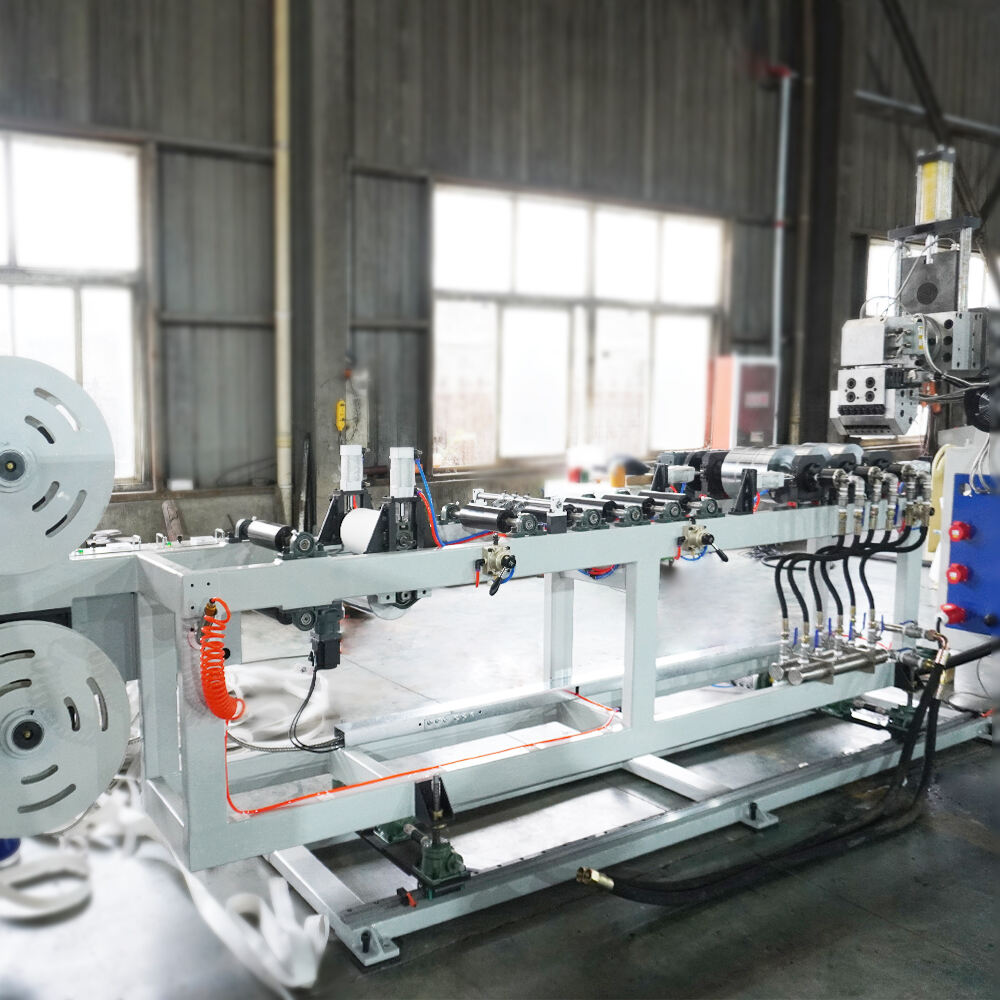

機械分析

自動かつ連続的な材料搬送を実現し、手動操作による煩雑さと不安定さを回避し、生産効率を向上させます。真空ポンプを使用して吸引および搬送することで、エネルギーを節約し、運転コストを削減できます。

このエクストルーダーはPEシート用にカスタマイズされており、熱可塑性樹脂を溶融・押出することで高性能なシートを作ることができます。

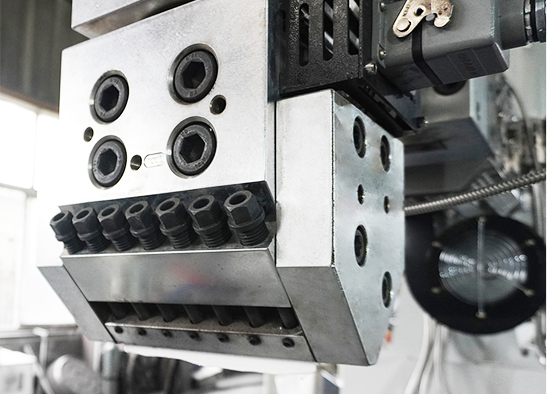

金型の主な機能は、高精度と高効率を持つPEシートを加工し形状を成形することです。カスタマイズされたPEシート金型は、シートの形状、サイズ、厚さを正確に制御し、最高の製品品質と性能を確保します。

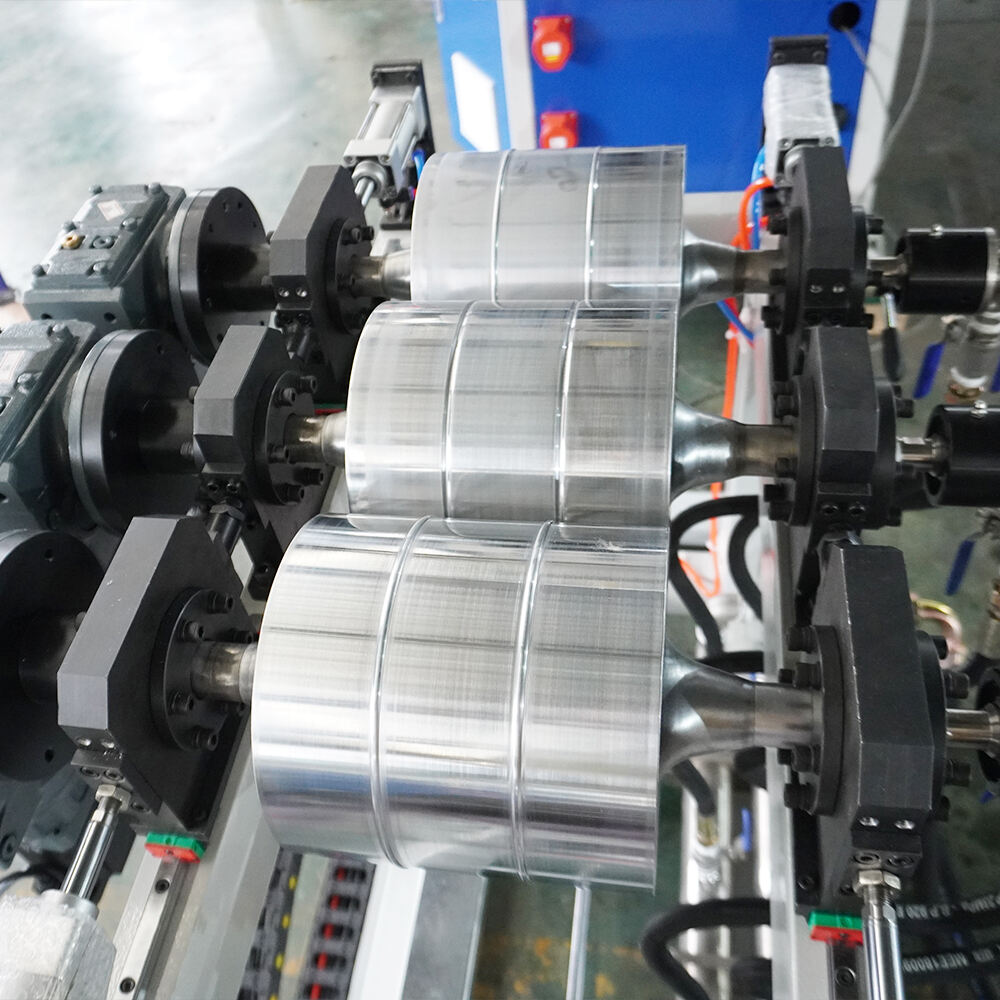

三軸ローラー押出機は、三つのローラーの回転と押出しにより、PE素材をローラー間で均一に押出し延ばし、最適な延展性と表面品質を実現します。私たちはこの押出機を同時に2枚のシートを作れるように設計しました。

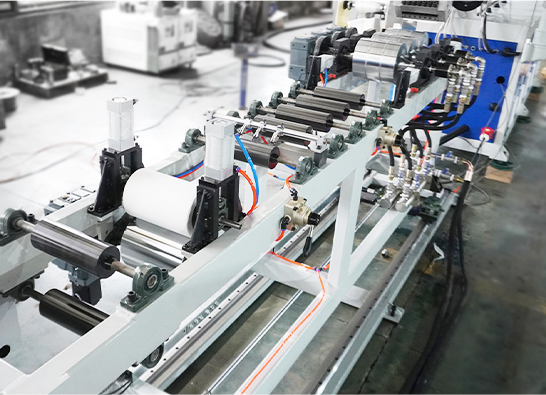

主な機能は、シートを引き、生産ライン上でシートが予定された速度と方向で移動することを確保することです。シートの速度を制御することで、生産プロセス中のシートの平坦性と品質が保証されます。

主に生産されたプラスチックシートを巻き取って収集するために使用されます。

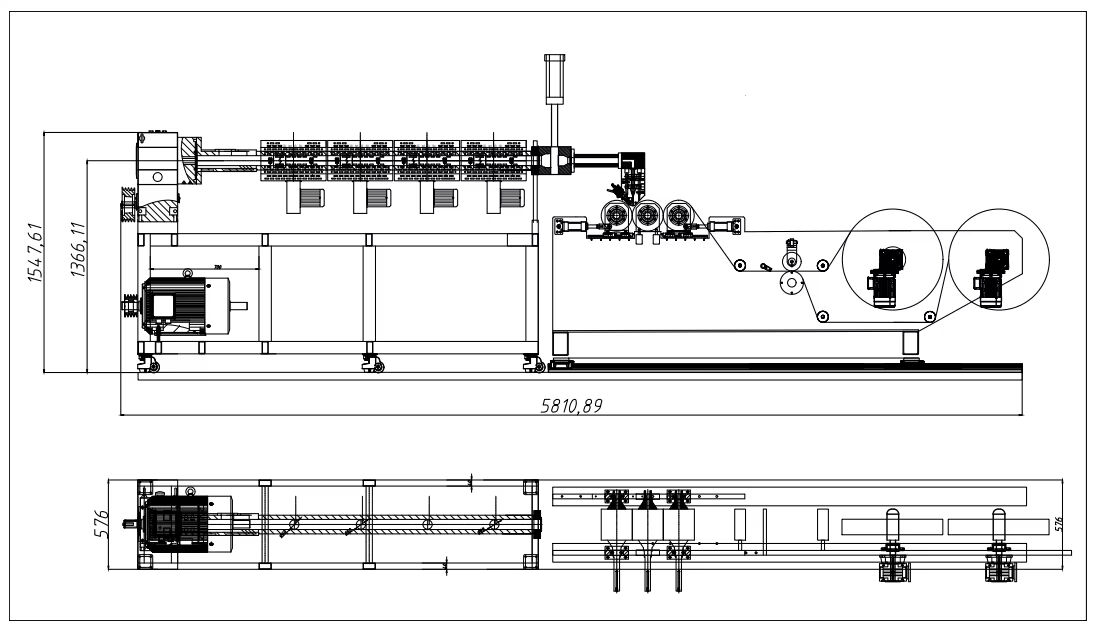

機械パラメータ

製品名: 実験室用プラスチックシートまたはストリップ押出機

シートの厚さ: 0.5mm~0.7mm

シートの幅: 53mm~55mm

最終製品: PEシート/ストリップ

出力: 15m/分、10kg/ロール

スクリュー設計: 単スクリュー

原材料: PET、PP、PE、PLA...

応用分野

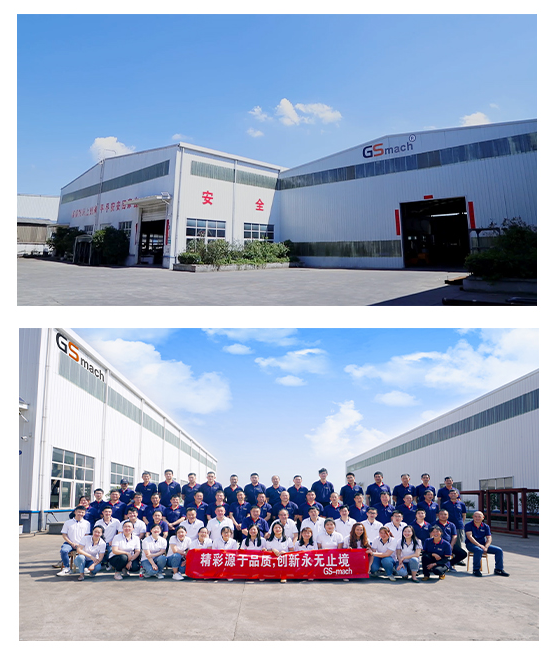

私たちについて

GS-Machは、CEおよびISO9001認証を取得したプラスチック、ゴム、化学機械の研究者、デザイナーおよびメーカーです。

世界市場に向けた方針で、私たちは人材の強化、革新、品質の向上、管理の改善に努め、お客様に最高の製品を提供し、GS-machを世界的トップクラスの機械製造業者およびサプライヤーにすることを目指しています。

私たちの事業は3つの部分で構成されています: GS-mach Extrusion、GS-mach Recycle、GS-mach Rubber Tech。

1) GS-mach Extrusion : プラスチック押出、顆粒化、押出成形、そして押出フィラメント用の機械の研究開発と製造に特化しています。

フィラメント押出。

2) GS-mach Recycle : 廃プラスチック、ゴム、化学品のリサイクル用機械の研究開発と製造に特化しています。

3) GS-mach Rubber Tech:ゴム機械の研究開発と製造に特化しています。

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - プライバシーポリシー