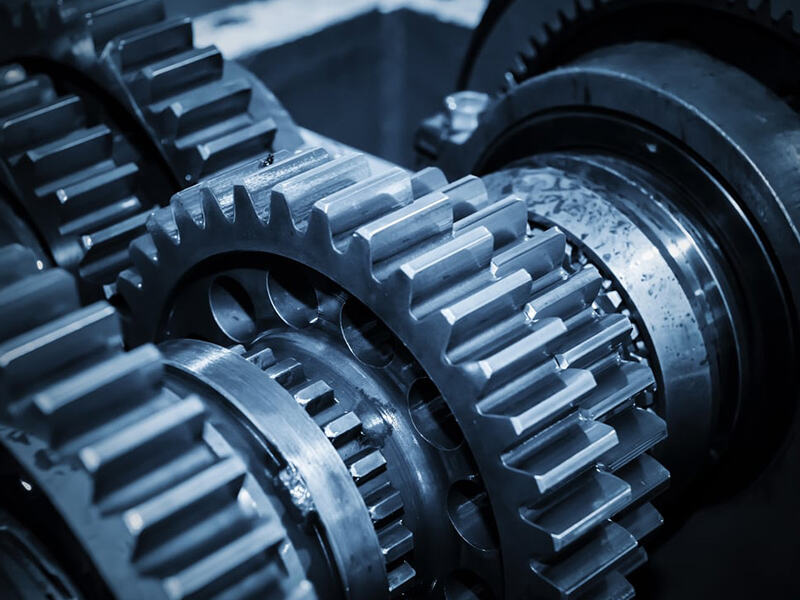

Maintenance of the gearbox of the twin-screw extruder

Maintenance of gearboxes:

1. The twin-screw extruder host gear box parts to be well ventilated, the working environment temperature should be in the range of 5-35 ℃.

2. Often check the amount of oil in the box gear lubricating oil, to ensure that the box has good lubrication of the transmission parts.

3. Attention to frequent inspection of the box body bearing parts, the oil temperature of the transmission box should not exceed 70 ℃ when working.

4. New put into use gear box work 250h after the need to replace the lubricant, after the oil is replaced. Later oil change time depends on the state of the oil,

it is recommended in the operation of 4000-8000 hours or once a year to replace.

5. Gear box should be carried out once a year for regular maintenance inspection.

The work is as follows:

(1) Open the gear box cover, check the transmission reducer gear working surface wear and meshing, if there is a meshing surface parts have burrs or

shallow pockmarks, available oil stone repair smooth; more serious wear of the gear.

(2) Check the wear of the bearings. Firstly, clean the bearings and check whether the inner jacket is cracked; observe the size of the airlift noise and the

size of the radial clearance; if no problem is found, add some grease and continue to use.

(3) Check whether the lubricant in the box is clean; if there are impurities or metal powder in the oil, filter the lubricant to remove the impurities and

then make up the amount of lubricant.

(4) After cleaning and checking the parts in the box, install the box cover; add sufficient grease to each bearing part and replace it with new oil. After

adding sufficient grease, replace the new oil seal and fasten the bearing cover.

(5) Clean the outside of the gear box to keep the equipment clean.

Principles for replacing parts in gearboxes:

1. If the involute meshing tooth surface of the gear appears deeper wear deep pits, work rotating noise and irregular, from time to time there is impact

vibration phenomenon, this gear should be replaced.

2. Ball bearing inner sleeve or jacket has cracks, ball frame damage, the radial clearance of the inner jacket is large, rotating jacket bearing rotating noise, etc.

After rolling bearing cleaning, if found to have one of the above damage phenomenon, rolling bearing should be replaced.