Teach you to understand the difference between single screw extruder and twin screw extruder

Extruder is a kind of plastic machinery, is a commonly used machinery in the modified plastic industry, widely used in polymer processing industry and other production and processing fields. Extruders can be divided into single screw extruder and twin screw extruder. Their working principles and application fields are different, and each has its own advantages and disadvantages.

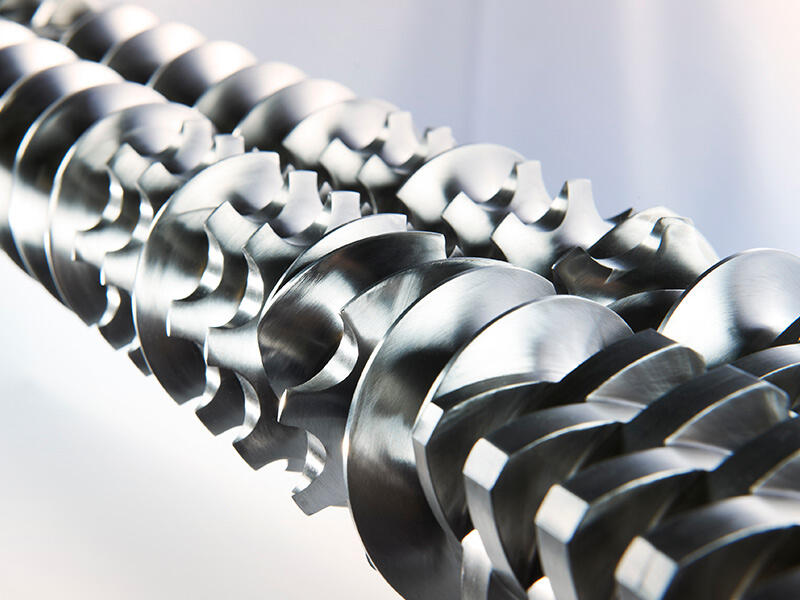

First of all, there are many differences between single screw extruder and twin screw extruder in plasticizing capacity, material conveying mode, speed cleaning and other aspects. As follows:

1. Different plasticizing ability: single screw is suitable for polymer plasticizing extrusion and granular material extrusion processing; Shear degradation of the polymer is minimal, but the material stays in the extruder for a long time. Twin screw mixing plasticizing ability, short residence time in extruder, suitable for powder processing.

2. Different material transport mechanisms: in single screw extruder, material transport is drag flow, solid transport process is friction drag, melt transport process is viscous drag. The friction coefficient of solid material and metal surface and the viscosity of melt material largely determine the transport capacity of single screw extruder. The material transportation in twin-screw extruder is positive displacement transportation. As the screw rotates, the material is forced forward by meshing threads. The capacity of positive displacement transportation depends on the proximity between the edge of one screw and the screw particles of the other screw. Large positive displacement can be obtained by using a tightly meshed counterrotating twin screw extruder.

3. Different speed occasions cleaning: the speed distribution in the single screw extruder is clear and easy to describe, while the situation in the twin screw extruder is more complex and difficult to describe. This is mainly due to the meshing area of the twin screw extruder. The complex flow in the meshing zone makes the twin-screw extruder have the advantages of full mixing, uniform heat transfer, strong melting capacity and good exhaust performance, but it is difficult to accurately analyze the flow state in the meshing zone.

4. Different self-cleaning: the shear speed of the twin screw extruder is fast, because the speed direction of the spiral bar and spiral groove in the meshing area is opposite, the relative speed is fast, and any accumulated material attached to the screw can be scraped off. It has a good self-cleaning effect, and the residence time of the material is short, and it is not easy to local degradation. Single screw extruders do not have this function.

In addition to different working principles, they have different application areas. Twin-screw extruder is widely used in physical and chemical modification of matrix resin, such as filling, strengthening, toughening, reactive extrusion, etc. Single screw extruders are mainly used in pipe, sheet, sheet and profile fields.

Application examples of twin screw extruder: glass fiber reinforced, fuel resistant granulation (such as nylon 6, nylon 66, polyester, polybutylene terephterate, polypropylene, polycarbonate, etc.). , high filler granulation (such as filling 75% CaCO3 PE and PP) and heat sensitive materials granulation, such as PVC and crosslinked polyethylene cable materials), concentrated masterbatch (such as filling 50% toner), antistatic masterbatch and alloy cable materials granulation (such as sheath and insulation material), cross-linked polyethylene pipe granulation (such as hot water crosslinking masterbatch), thermosetting plastic mixing extruder, such as phenolic resin, epoxy resin and powder coating) , hot melt adhesive and polyurethane reaction extrusion granulation (such as EVA hot melt adhesive and polyurethane), K resin and SBS devolatilization granulation, etc.

Single screw extruder application examples: suitable for PP-R pipe, PE gas pipe, PEX crosslinking pipe, aluminum-plastic composite pipe, ABS pipe, PVC pipe, HDPE silicon core pipe and various co-extruded composite pipe; Suitable for the extrusion of PVC, polyethylene terephthalate, polystyrene, polypropylene, polycarbonate and other profiles and plates, as well as wire, rod and other plastic extrusion; By adjusting the speed of the extruder and changing the structure of the extruder screw, it can be used to produce various plastic profiles, such as polyvinyl chloride and polyolefin.