Why does the twin-screw underwater cutting granulator make good material?

The art of life lies in the care of details, while the miracle of industry comes from the power of innovation. When meticulousness, innovation and efficiency are combined, there is the miraculous existence of the twin-screw underwater cutting granulator.

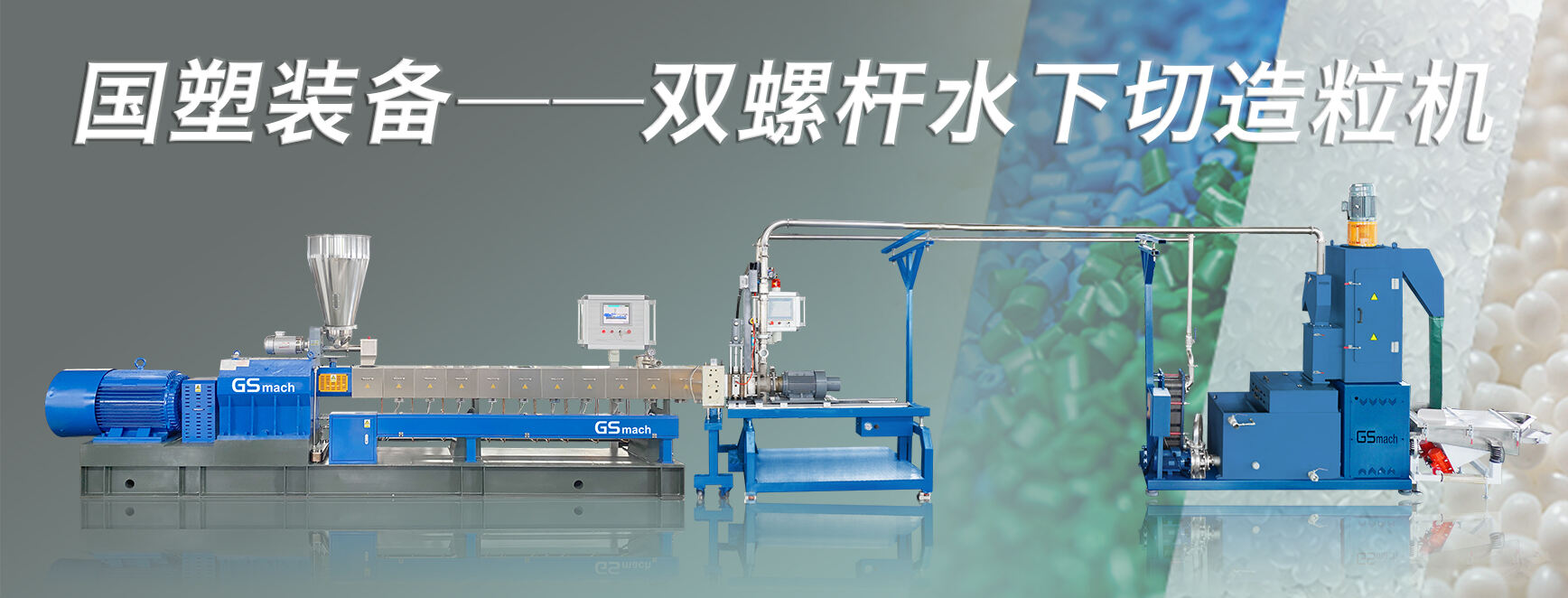

Twin-screw underwater cutting granulator is an outstanding representative of underwater cutting technology. It cleverly combines the cutting process with the granulation process, so that the raw materials can be precisely and meticulously cut underwater, thus producing high-quality material.

Firstly, twin-screw underwater cutting pelletising has many advantages over traditional water ring pelletising, water slat pelletising and hot cutting pelletising.

One of them is the ability to provide a wider range of applications. Whether it is heat-sensitive plastics, polymers with small particle diameters, or highly viscous polymers, the twin-screw underwater cutting granulator is easily capable of handling them, ensuring product diversity and flexibility.

Secondly, the twin-screw underwater cutting granulator can effectively control the temperature during the processing. As the cutting process is carried out underwater, the raw material can be cooled quickly and kept within the ideal temperature range, avoiding the unfavourable effects of overheating or overcooling on the quality of the material. As a result, the resulting material has higher uniformity and consistency, and the quality is more stable and reliable.

In addition, the twin-screw underwater cutting granulator adopts a unique cutting principle, which makes the surface of the material smooth and even, without breaking or producing uneven particles. This innovative design not only ensures the aesthetic appearance of the material, but also ensures the structural and performance integrity of the material inside, making it more suitable for subsequent processing and application.

In addition, the twin-screw underwater cutting granulator is also characterised by high efficiency. Its excellent design enables the raw materials to be fully sheared and mixed during the cutting process, which improves the production efficiency. At the same time, as the cutting process is carried out underwater, it greatly reduces energy consumption and noise generation, achieving the goal of environmental protection and energy saving.

All in all, twin screw underwater cutting granulator has become an indispensable and important tool in modern manufacturing industry with its excellent performance and outstanding innovation. It brings us high-quality material through fine cutting and efficient granulation, and adds new vitality to the development of industrial production. Whether it is the improvement of product quality or the improvement of production efficiency, twin-screw underwater cutting granulator plays an indispensable role and leads the innovative trend of the industry.