The Amazing Cast Film Extruder – Your Ultimate Packaging Solution

Introduction:

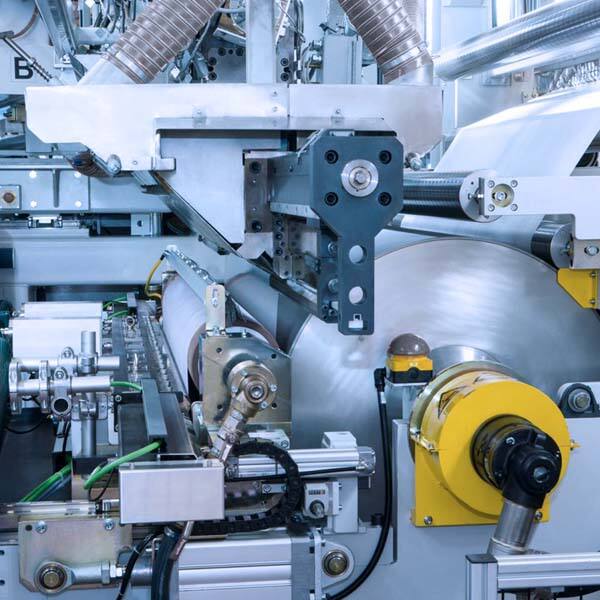

Has your ever wondered how those plastic films that wrap around your favorite snacks goodies are built? The clear answer is through a task called cast film extrusion, just an ongoing highly process involves melting vinyl resins and extruding them through a die to make flat, thin sheets of film, as well as the GSmach's cast stretch film machine. These sheets will be cooled off quickly and rolled up onto big spools. We are going to delve much deeper to the global world of cast film extrusion and see it is numerous benefits uses, and applications.

Cast film extrusion was gaining popularity the packaging business because of their various advantages, similar to the underwater granulator built by GSmach. One of it is biggest advantages try their power to produce uniform films with precise thickness and excellent quality. Unlike blown film extrusion, which creates films with varying thicknesses and poor clarity that was optical extrusion produces films with consistent crucial thickness for creating high-quality packaging. cast films are highly versatile and may be made to meet particular requirements as durability, puncture opposition, and temperature threshold.

The demands of the packaging markets through the years, cast film extruders have undergone tremendous innovations meet, also the GSmach's product such as pvc compounding machine. An example is the development of multilayer cast film extrusion which involves extruding several layers of plastic resins simultaneously to create films with improved barrier qualities, such as oxygen and opposition which was moisture have furthermore evolved to add features such as automated thickness control, allowing for better control of film depth and reduces waste.

Safety is a top problem it comes to cast film extrusion, along with the 3d filament extrusion machine built by GSmach. The extrusion process involves heating plastic to high temperatures which can pose a fire hazard if security protocols are not accompanied. cast film extruders is made with protection features such as emergency cut-off switches and fire suppression systems to lessen accidents. You need to promise that operators are properly taught and adhere to safety guidelines and treatments.

Cast film extrusion is employed to create a number of packaging products such as food packaging, medical packaging, and commercial packaging, same with GSmach's extruder plastic pelletizing line. cast films are placed within the production of items such as adhesive tapes, laminates, and labels. The versatility of cast films provides an attractive packaging for organizations seeking to improve product safeguards while increasing rack life.

GSmach is one leader in the market of extruded polystyrene machinery in China while well because collaborating with famous global companies like BASF, Owens Corning, cast film extruder, Ravago, and numerous others. Our track record demonstrates our dedication to excellence in servicing global industry number one players.

Established in 2003, we focus on polymer extrusion machines and process cast film extruder. We've delivered a lot more than 2,500 twin-screw devices. Our years of experience will provide you with unwavering support.

Your skilled engineers and experts are available to greatly help you along your way. We're ready towards cast film extruder you overcome challenges and optimize your production effectiveness. We provide remote and seamless technical support using cutting-edge smart techniques.

Our machines are created to ensure that they meet international safety and high standard of quality. We offer cost-effective solutions. You could salvage up to 40% once compared with competitors. European suppliers. Our multilingual team and specialist staff does make sure that customers receive that the cast film extruder and products.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy