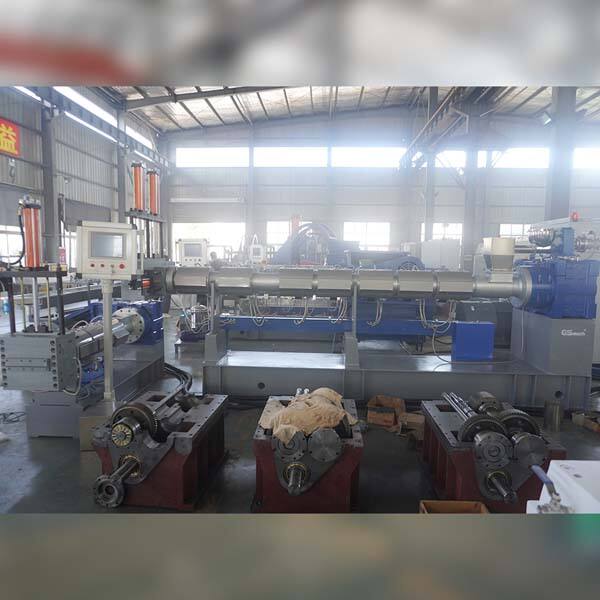

The Amazing Lab Extruder Device: Innovation and Safety readily available with GSmach laboratory extruder.

Trying to find a lab extruder machine that can help you produce materials which is usually safe, efficient, along with top quality? Search no further set alongside the GSmach lab extruder machine. This method is a little very advanced associated with the assistance to make a numerous materials, from synthetic materials and synthetic to pharmaceuticals and foods. We intend to explore the options that can be numerous come easily with lab extruder products, additionally their features which may be measures which is often revolutionary and safety.

Lab extruder machines offer a myriad of benefits that make them an ideal choice for almost any industrial or laboratory setting. First and foremost, these units are efficient, allowing you to produce large samples of product in a short amount of time. Additionally, they are capable of creating materials with precise physical properties such as hardness, melting points, and viscosity. GSmach lab scale extruder are extremely versatile, able to work with a wide range of materials and producing a variety of end products.

Lab extruder machines are the results of years of research and development, and they are constantly being improved with new features and capabilities. Some of the latest innovations of GSmach lab extruders include advanced control systems that enable users to monitor and adjust the machine's output in real-time, as well as high-performance materials that enhance both efficiency and safety. These lab extruders are available in a variety of sizes and designs, making it easier than ever to find a machine that fits your specific needs.

Safety is a top priority when it comes to lab extruder machines, and for good reason. These units operate at high temperatures and pressures, and they can be dangerous if not used properly. However, GSmach mini lab extruder come with a range of safety features to protect users from harm. For example, they may include sensors that detect over-temperature or pressure, automatic shut-off systems, and safety interlocks that prevent the machine from running if any safety protocols are not met.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with lab extruder machine.

Our equipment is in line with international standards of safety and quality offering efficient systems. Salvage significant amount, up to 40%, in contrast to different lab extruder machine. Our expert team and multilingual service ensure both pleased products and unmatched customer service.

GSmach is the market leader in China for extruded polystyrene equipment lab extruder machine with well-known organizations like BASF, Owens Corning ISOFOAM Ravago and many more. Our track record demonstrates our dedication to portion the top industry players throughout the world.

The team of experts and engineers will likely get there to assist you in your lab extruder machine. We're prepared to simply services you overcome obstacles and improve your production performance. Currently remote and seamless technical support with cutting-edge, smart techniques.

Lab extruder machines are highly versatile and can be used in a wide range of industries and applications. Some of the most common uses of GSmach labtech twin screw extruder products include the manufacturing of synthetic pellets for injection molding, the extrusion of plastic tubing for medical devices, and the formulation of pharmaceuticals and health supplements. They can also be used to produce food items such as snacks and pasta, as well as commercial materials like adhesives and sealants.

While lab extruder machines may seem complex, they are simple to use with a little bit of training. To begin, you'll need to load your raw material into the machine. Once your material is loaded, you'll need to set the machine to the desired pressure and temperature settings. Once the machine has reached the appropriate temperature and pressure, you can begin extruding your material. It's important to note that lab extruder machines should only be operated by trained professionals who know how to properly load and operate the machine.

Lab extruder machines require regular maintenance and servicing to ensure optimal performance. Many manufacturers offer maintenance and service packages to keep your machine running smoothly, so you should always follow their recommended maintenance schedule to avoid downtime and potential safety hazards. If you ever encounter any issues with your machine, you should contact the manufacturer or a qualified technician immediately to ensure that any problems are resolved quickly and effectively.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy