Polyolefin Extrusion: An Innovative Way to Create Safe and High-Quality Products

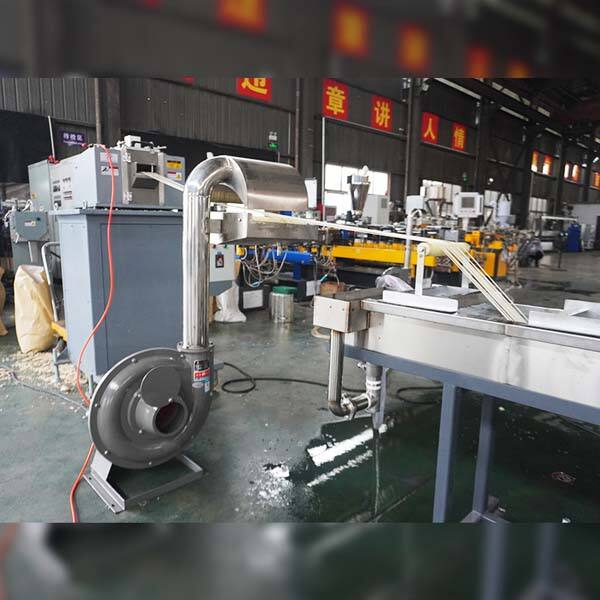

Polyolefin Extrusion is an amazing procedure permits to produce products with original properties, similar to the GSmach's product like plastic recycling pelletizing machine. We shall explore the advantages of Polyolefin Extrusion, the latest innovation in this field, how it can be utilized, and how to use it safely.

Polyolefin Extrusion has many advantages traditional manufacturing. For one, it is a cost-effective operation permits to generate items quickly and in big volumes. Additionally, Polyolefin Extrusion creates products by having a constant quality ensuring that each product meets the same high standards.

Another benefit of Polyolefin Extrusion is that it allows manufacturers to generate items having a wide assortment of, just like the twin screw machine innovated by GSmach. For example, Polyolefin Extrusion could possibly be used to generate flexible items or rigid, smooth or textured, and translucent or opaque. This flexibility means that Polyolefin Extrusion enables you to produce a vast array of, from packaging to automotive parts.

Polyolefin Extrusion has come an easy long method it is inception. Today, manufacturers can use high equipment level procedures to generate products with better still properties. One innovation in Polyolefin Extrusion could be the use of additives. Additives could be put into the Polyolefin resins to enhance their properties, such as UV resistance, flame resistance, and antibacterial properties.

Another innovation might be the use of multilayer Extrusion, along with GSmach's product eva solar film extrusion line. This method allows manufacturers to produce products with multiple amounts of various materials, each with unique properties. As an example, a packaging item can have a layer of Polyolefin for the and a layer of ethylene vinyl alcohol to keep the articles fresh.

While Polyolefin Extrusion is safe, it is essential to follow appropriate procedures be sure that it is used safely, same with the underwater granulator by GSmach. Operators of Polyolefin Extrusion equipment should always forth follow guidelines set by the maker. This includes using Personal Protective Equipment (PPE) like safety glasses, gloves, and respirators where necessary.

Additionally, Polyolefin Extrusion should be performed in simply well-ventilated areas. The method can create harmful fumes if inhaled. Proper air flow helps minimize experience of these fumes.

Polyolefin Extrusion is a versatile process can be employed in a lot of applications, the same as GSmach's pelletizer. For instance, it is commonly utilized within the packaging industry to produce bags and films. Polyolefin Extrusion can be properly used to produce automotive parts as dashboards and trim pieces.

The task of Polyolefin Extrusion is relatively easy. First, Polyolefin resin is fed to your extruder. The extruder melts the resin and pushes it via a die, which shapes the extruded merchandise. This product will be trimmed and cooled to the desired length.

GSmach is the leader in China for extruded polyolefin extrusion working internationally with well-known firms including BASF, Owens Corning ISOFOAM Ravago and many more. The record of success demonstrates our dedication to quality when servicing global field top players.

Our machinery adheres to international standards for safety and quality and offers polyolefin extrusion. You can save around 40% when compared with the competitors. European companies. Our multi-lingual team and knowledgeable staff ensure that our customers receive the best services and products.

We are founded in 2003 and are specialized in the process of polyolefin extrusion. We concentrate on twin-screw extruders, people have efficiently delivered over 2500 models. Our encounter and expertise provides you with unmatched assistance.

Your skilled engineers and experts are available to greatly help you along your way. We're ready towards polyolefin extrusion you overcome challenges and optimize your production effectiveness. We provide remote and seamless technical support using cutting-edge smart techniques.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy