GSmach provides advanced pelletizing line for all kinds of filler masterbatch.

We design the extruders for filler masterbatch, according to the output,

formula and final application as your request.

Filler Masterbatch are concentrates of CaCO3 or Talc or BaSO4 in a polymer base.

Table of Contents

The Basic Formula

| Base Resin | Filler Type | Additives |

| PP | CaCO3 55-85% | PE wax |

| PE | Talc 25-60% | White Oil |

| PS | BaSO4 40~70% | Anti oxidant |

Applications

Filler masterbatches are used in injection, blow-moulding, film(One layer or Multiple layer), sheet and tapes applications.

They offer the following advantages:

a) Injection & blow-moulding

Lower raw materials cost, as they are usually more economic than polymer resins

Increased output due to faster mould cooling

Reduction of colour masterbatch requirement

Higher resistance to heat deflection, higher rigidity and stiffness

Improved dimensional stability, weldability and printability

Addition rate of FILLER masterbatches in injection & blow-moulding applications can be up to 50 %, however, most usual levels are between 5-30 %.

b) Film, sheet, sacks, bags, raffia

Lower raw materials cost, as they are usually more economic than polymer resins

Reduction of colour masterbatch requirement

Higher stiffness, paper-like effect

Improved weldability and printability

Improved anti-blocking properties

Better bubble stability

Addition rate of FILLER masterbatches in film applications is 2-20 %.

c) PE & PP tapes

Antifibrillation (also known as anti splitting)

Lower raw materials cost, as they are usually more economic than polymer resins

Reduction of colour masterbatch requirement

Higher stiffness

Improved weldability and printability

Improved anti-blocking properties

Improved weaving ability

Easier processing

Usual addition rate of FILLER masterbatches in tapes is 3-8 %.

d) HDPE & PP Pipe

Replacing expensive white masterbatch with its high white degree

Lower raw materials cost, as they are usually more economic than polymer resins

Higher stiffness

Smooth pipes with lower coefficient of friction to better prevent them from blocking

Being less possible to be brittel in low temperature due to its excellent cold resistance

Usual addition rate of FILLER masterbatches in tapes is 5-30 %.

Processing of Filler Masterbatch

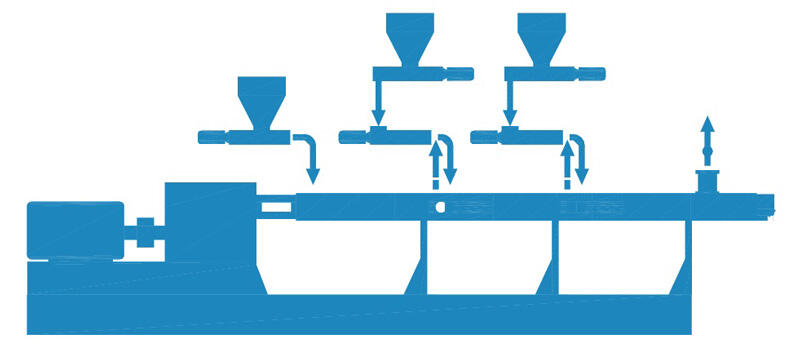

a) Feeding System

There two feeding system:

Volumetric feeding system

1.Weight the raw material separately according to the formula

2.Then put all the material into high speed mixer for 5~10minutes mixing

3.Discharge the material into spiral loader

4.Loading the material into the hopper of volumetric feeder

Loss-in-weight feeding system (automatically and higher accuracy)

1.Put the raw material into each tank on the ground.

2.Vacuum loader will convey each component into the storing silo.

3.The raw material will fall into the loss-in-weight feeder automatically. The feeding system

will feed the material separately into extruder according to your formula setting one the HMI.

(Loss-in-weight feeding system & Side Force Feeder)

b) Technical Specifications of Extruder

According to your application & output, there’re many different choice on extruders.

Twin Screw Extruder

| Type | Screw diameter (mm) | Power(kw) | Quantity (kg/h) |

| GS20 | 21.7 | 4 | 5~15 |

| GS25 | 26 | 11 | 5~55 |

| GS35 | 35.6 | 15 | 10~40 |

| GS50 | 50.5 | 55 | 120~200 |

| GS52 | 51.4 | 90 | 270~450 |

| GS65 | 62.4 | 90 | 255~400 |

| GS75 | 71 | 132 | 450~750 |

| GS95 | 93 | 315 | 950~1600 |

| GS135 | 133 | 750 | 2250~3750 |

Twin Screw Extruder

| Type | Screw diameter (mm) | power(kw) | Screw speed (rpm) | output(kg/h) |

| GS36 | 36 | 18.5-30 | 400-600 | 50-150 |

| GS52 | 52 | 75-90 | 400-600 | 250-800 |

| GS65 | 65 | 90-160 | 400-600 | 500-1000 |

| GS75 | 75 | 132-250 | 400-600 | 1000-1500 |

| GS95 | 95 | 200-315 | 400-600 | 1500-2500 |

Kneader + Single Screw Extruder

| Model | Kneader | Kneader Power(KW) | Screw Dia. | L/D | Output |

| GSD100 | 35L | 55KW | 100mm | 16-22:1 | 100~200kg/h |

| GSD120 | 55L | 75KW | 120mm | 16-22:1 | 200~300kg/h |

| GSD120 | 75L | 110KW | 120mm | 16-22:1 | 300~500kg/h |

| GSD150 | 110L | 160KW | 150mm | 16-22:1 | 600~800kg/h |

| GSD180 | 150L | 220KW | 180mm | 16-22:1 | 800~1200kg/h |

Kneader + Twin Screw Extruder

| Model | Main Machine | Kneader | Output(KG/H) | |

| GS50/100 | GS50 Twin Screw Extruder | 55L | ||

| GS100 Single Screw Extruder | 60~90 | |||

| GS65/150 | GS65 Twin Screw Extruder | 75L | 500~600 | 400~600KG/H |

| GS150 Single Screw Extruder | 60~90 | |||

| GS75/180 | GS75 Twin Screw Extruder | 110L | 500~600 | 600~800KG/H |

| GS180 Single Screw Extruder | 60~90 | |||

| GS95/200 | GS95 Twin Screw Extruder | 150L | 400~500 | 1000~1500KG/H |

| GS200 Single Screw Extruder | 60~90 |

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy